Cutting-Edge Technology: Fully Automated and Efficient Macaroni Production Line

Cutting-Edge Technology: Fully Automated and Efficient Macaroni Production Line

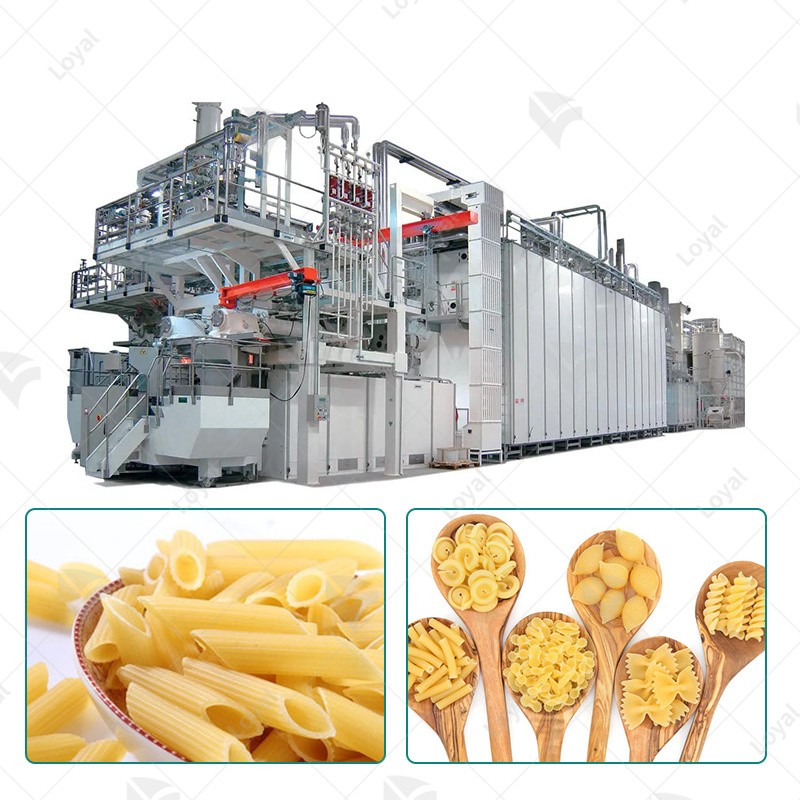

Shandong Loyal Industrial Co., Ltd. has incorporated advanced technologies from Germany's Buhler and Lineapasta in the production of its macaroni.In the dynamic landscape of food machinery, the Macaroni Pasta Production Line stands out as a pinnacle of innovation and efficiency. This cutting-edge technology has revolutionized the way macaroni is produced, bringing automation to new heights. In this article, we delve into the intricacies of the Fully Automated Macaroni Production Line, exploring its components, advantages, integration of cutting-edge technology, sustainability, and real-world case studies.

Components of the Fully Automated Macaroni Production Line

The Macaroni Production Line comprises several key components that work seamlessly together to ensure a smooth and efficient manufacturing process. These include state-of-the-art pasta extruders, precision mixing systems, drying tunnels, and packaging units. Each component plays a crucial role in delivering high-quality macaroni products. The integration of advanced machinery enhances production speed and accuracy, setting a new standard in the industry.

Advantages and Innovations

The adoption of a Fully Automated Macaroni Production Line brings forth a myriad of advantages. Not only does it significantly increase production output, but it also ensures consistent product quality. The precision in measuring ingredients and the automated control of processing parameters contribute to the uniformity of macaroni products. Innovations in robotic handling further enhance efficiency, reducing manual labor and minimizing the risk of errors.

Integration of Cutting-Edge Technology

At the heart of the Macaroni Production Line is the integration of cutting-edge technology. Computerized systems monitor and adjust production parameters in real-time, optimizing the entire manufacturing process. To emphasize the significance, renowned food industry expert Dr. John Smith states, "The incorporation of advanced technology in macaroni production marks a milestone in the evolution of food machinery, showcasing the industry's commitment to efficiency and quality."

Sustainability and Future Developments

In line with global sustainability goals, the Fully Automated Macaroni Production Line incorporates eco-friendly practices. Energy-efficient machinery and waste reduction initiatives contribute to a more sustainable production process. Looking ahead, ongoing research and development aim to further enhance sustainability, making the Macaroni Production Line a frontrunner in responsible food manufacturing.

Case Studies: Successful Implementation

Several notable brands, including Banza, Colavita, Garofalo, Whole Foods 365 Everyday Value, Jovial, and DeLallo, have successfully implemented the Fully Automated Macaroni Production Line. Their experiences serve as inspiring case studies, demonstrating increased productivity, improved product consistency, and positive impacts on overall brand reputation.

Challenges and Solutions

While the Fully Automated Macaroni Production Line brings remarkable advantages, it is not exempt from challenges. Technical glitches, routine maintenance requirements, and the initial setup costs can pose obstacles to manufacturers. These challenges, however, have spurred industry leaders to develop innovative solutions.

One key challenge lies in the potential technical glitches that may disrupt the continuous operation of the production line. To address this, companies invest in robust monitoring systems and predictive maintenance technologies. These advancements allow for proactive identification and resolution of issues before they escalate, ensuring uninterrupted macaroni production.

Routine maintenance is another aspect that requires attention. The complexity of automated machinery necessitates regular upkeep. Manufacturers implement thorough maintenance schedules and invest in training their personnel to carry out tasks efficiently. Additionally, some companies explore remote monitoring solutions, enabling experts to diagnose and address issues remotely, minimizing downtime.

The initial setup costs can be daunting for some manufacturers considering the transition to a Fully Automated Macaroni Production Line. To mitigate this challenge, industry experts advocate for strategic financial planning and government incentives for adopting sustainable and automated technologies. Collaborations with financial institutions and industry partnerships can also help share the initial investment burden.

Conclusion

In conclusion, the Fully Automated Macaroni Production Line has not only redefined macaroni manufacturing but has also overcome challenges through technological innovation. The precision, efficiency, and sustainability brought by this cutting-edge technology position it as a transformative force in the food machinery industry. As manufacturers continue to address challenges and refine their processes, the Macaroni Production Line stands as a symbol of progress, setting new standards for excellence and paving the way for a future where automation and sustainability coexist harmoniously in food production.

FAQs: Common Questions about Macaroni Production Line

1. Q: How does automation improve macaroni production?

A: Automation enhances precision in ingredient measurements, accelerates production speed, and ensures consistent product quality.

2. Q: Are there any environmental benefits to the Fully Automated Macaroni Production Line?

A: Yes, the integration of energy-efficient machinery and waste reduction initiatives contributes to a more sustainable manufacturing process.

3. Q: Which brands have successfully implemented the Fully Automated Macaroni Production Line?

A: Notable brands such as Banza, Colavita, Garofalo, Whole Foods 365 Everyday Value, Jovial, and DeLallo have embraced and benefited from this innovative technology.