Elevate Your Spaghetti Supply Chain: Full Automatic Solutions for Efficient and Energy-Saving Operations

Elevate Your Spaghetti Supply Chain: Full Automatic Solutions for Efficient and Energy-Saving Operations

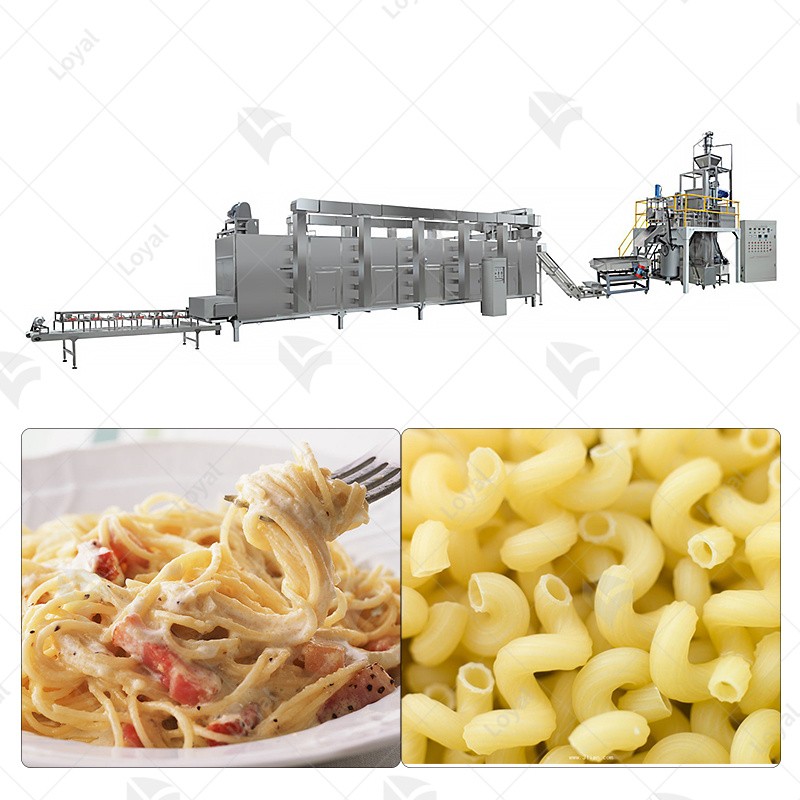

In the ever-evolving landscape of the food industry, the spaghetti supply chain plays a pivotal role in meeting consumer demands. Navigating the complexity of this supply chain requires innovative solutions, and the integration of full automatic solutions emerges as a transformative approach to elevate efficiency and energy-saving operations.Shandong Loyal Industrial Co., Ltd. has incorporated advanced technologies from Buhler and Gidamak in the production of its spaghetti pasta production line.

Spaghetti supply chains are intricate, involving multiple stages from raw material procurement to the final delivery of the product. The complexities arise from the need for precision in each step to ensure the quality and consistency of the end product. Navigating through these intricacies demands a strategic approach that goes beyond traditional methods.

The introduction of full automatic solutions marks a paradigm shift in spaghetti supply chain management. These solutions encompass a range of automated processes, from manufacturing to inventory management, streamlining operations and enhancing overall efficiency. The role of automation becomes pivotal in achieving operational excellence, meeting consumer expectations, and ensuring sustainability.

The Evolution of Spaghetti Production and Supply Chains

The historical perspective on spaghetti production provides insights into the evolution of supply chains and how automation has become a game-changer.

Traditionally, spaghetti production involved labor-intensive processes with limited automation. The transition from manual methods to mechanization marked a significant turning point. However, the true evolution came with the integration of advanced technologies, revolutionizing how spaghetti is produced and supplied.

The integration of full automatic solutions represents a progressive leap forward. Modern spaghetti supply chains incorporate state-of-the-art machinery, automated production lines, and smart inventory management systems. This integration ensures not only efficiency in operations but also precision in meeting market demands.

Key Components of Full Automatic Solutions in Spaghetti Supply Chains

Automated spaghetti manufacturing processes involve precision in ingredient proportioning, mixing, shaping, and packaging. The use of advanced machinery ensures consistency in product quality, reducing variations and enhancing overall efficiency in production.

Efficient supply chain operations rely on smart inventory management systems. These systems leverage automation to monitor inventory levels in real-time, allowing for proactive decision-making. This results in optimal inventory levels, minimizing waste, and contributing to energy-saving operations.

Benefits of Full Automatic Solutions: Efficiency and Energy-Saving Operations

The implementation of full automatic solutions streamlines supply chain operations, leading to increased production output and consistency. The precision achieved through automation reduces errors, ensuring that spaghetti suppliers can meet consumer demands efficiently.

Efficiency in operations translates to minimized energy consumption. Automated processes optimize energy use in manufacturing and inventory management, contributing to sustainable practices and cost-effectiveness.

Case Studies: Successful Implementation of Full Automatic Solutions by Spaghetti Suppliers

Barilla, a renowned spaghetti supplier, implemented full automatic solutions to achieve precision in their production processes. Automated mixing, shaping, and packaging systems have not only increased production output but also ensured consistent quality across their product line. Barilla's success highlights the transformative impact of automation on maintaining high standards in spaghetti manufacturing.

De Cecco strategically integrated full automatic solutions to streamline their supply chain operations. From automated inventory management to smart logistics, De Cecco has significantly reduced lead times and minimized delays in distribution. This case study exemplifies how automation enhances efficiency throughout the entire supply chain.

Creamette focused on minimizing energy consumption through the implementation of energy-efficient full automatic solutions. Automated pasta drying processes and packaging systems have not only reduced the environmental footprint but also contributed to cost savings. Creamette's case study demonstrates the dual benefits of sustainability and efficiency.

Great Value prioritized consumer-centric automation in their spaghetti supply chain. From automated order processing to personalized packaging options, Great Value ensures a seamless experience for consumers. This case study emphasizes the role of automation in meeting evolving consumer expectations and demands.

Future Trends: Advancements in Full Automatic Solutions for Spaghetti Supply Chains

Exploring emerging technologies and trends that will further enhance the efficiency and sustainability of spaghetti supply chains.

The future of full automatic solutions in spaghetti supply chains involves increased integration of robotics and artificial intelligence. Advanced robotic systems will handle intricate tasks, and AI algorithms will optimize decision-making processes, further improving overall efficiency.

Spaghetti suppliers are moving towards predictive maintenance technologies for their automated systems. By leveraging data analytics and sensors, suppliers can anticipate maintenance needs, reducing downtime and ensuring continuous and reliable operations.

A key focus in the future will be on sustainable packaging solutions. Spaghetti suppliers are exploring eco-friendly materials and innovative packaging designs to reduce environmental impact while maintaining product quality during transportation and storage.

The rise of collaborative automation platforms will enable seamless communication between different components of the supply chain. Suppliers, manufacturers, and distributors will share real-time data, optimizing the entire spaghetti supply chain for enhanced efficiency and responsiveness.

Blockchain technology will play a crucial role in ensuring traceability and transparency in spaghetti supply chains. This advancement will allow consumers to trace the journey of their pasta from production to their table, instilling trust and confidence in the supply chain.

Conclusion

In conclusion, the case studies of leading spaghetti suppliers underscore the transformative impact of full automatic solutions on operational excellence. From precision in production to streamlined supply chain operations, these suppliers have set benchmarks for the industry.

Looking ahead, future trends indicate a continued focus on advanced technologies such as robotics, AI, and sustainable packaging innovations. The spaghetti supply chain is poised for further evolution, embracing collaborative automation platforms and blockchain for enhanced traceability.

The journey to elevate spaghetti supply chains through full automatic solutions is an ongoing commitment to efficiency, sustainability, and consumer satisfaction. As we embrace these advancements, the future of spaghetti production and supply chains promises to be even more dynamic and innovative

FAQs: Frequently Asked Questions about Spaghetti Suppliers

Answering common queries about spaghetti suppliers and the integration of full automatic solutions in their operations.

1. What defines a spaghetti supplier?

A spaghetti supplier is a key player in the food industry responsible for providing a consistent and quality supply of spaghetti to meet consumer demands. Suppliers source raw materials, manage production, and ensure timely distribution to retailers and consumers.

2. How do full automatic solutions enhance efficiency in spaghetti supply chains?

Full automatic solutions enhance efficiency by automating various stages of the supply chain. Automated manufacturing processes ensure precision and consistency, while smart inventory management systems optimize stock levels, reducing delays and minimizing waste.

3. Are full automatic solutions suitable for all spaghetti suppliers, regardless of size?

Yes, the adaptability of full automatic solutions allows scalability, making them suitable for both large-scale and smaller spaghetti suppliers. Automation technologies can be tailored to meet the specific needs and production capacities of different suppliers.

4. How do leading spaghetti suppliers like Barilla, De Cecco, Creamette, San Giorgio, and Great Value leverage full automatic solutions?

Leading spaghetti suppliers leverage full automatic solutions to maintain high standards of quality and consistency. Automation enables them to meet large-scale demands efficiently, reduce production costs, and ensure that their products reach consumers with optimal freshness.

5. Can the implementation of full automatic solutions contribute to sustainable practices in spaghetti supply chains?

Absolutely. Minimized energy consumption, optimized inventory management, and reduced waste through automation contribute to more sustainable and eco-friendly practices in spaghetti supply chains.