Fully Automated Macaroni Pasta Machine: High-Efficiency and Energy-Saving Solutions

Fully Automated Macaroni Pasta Machine: High-Efficiency and Energy-Saving Solutions

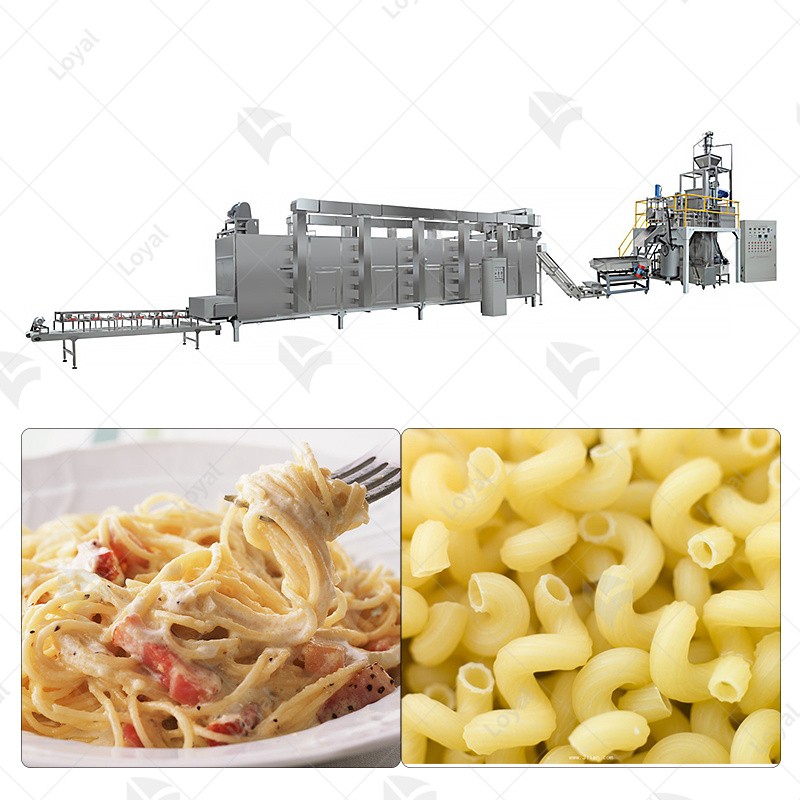

Shandong Loyal Industrial Co., Ltd. has incorporated advanced technologies from Germany's Buhler and Italy's GEA in the production of its macaroni.In the ever-evolving landscape of the food industry, automation has emerged as a transformative force, revolutionizing the way we produce and manufacture our favorite culinary delights. This article delves into the concept of the Fully Automated Pasta Processing Equipment, exploring the intersection of technology, efficiency, and energy conservation in modern pasta production. As we navigate through the intricacies of this advanced machinery, the goal is to shed light on the paramount importance of embracing high-efficiency and energy-saving solutions for the future of pasta manufacturing.

Evolution of Pasta Manufacturing

The journey of pasta manufacturing has witnessed a remarkable evolution, transitioning from traditional methods to embracing automation. This section takes a historical excursion, tracing the roots of pasta manufacturing methods. With the introduction of automation, a paradigm shift occurred, fundamentally altering the dynamics of pasta production. The narrative unfolds as we explore the compelling reasons behind the industry's move towards fully automated processes, emphasizing the pursuit of enhanced efficiency and energy conservation.

Features and Functionality

Unlocking the intricacies of a Fully Automated Macaroni Pasta Machine, we delve into its key features and functionality. Bold innovation defines these machines, streamlining the pasta manufacturing process with precision and speed. A detailed breakdown of the machine's components sheds light on how each element contributes to not only high efficiency but also substantial energy savings. Bold technological advancements are spotlighted, underscoring their role in elevating the standards of modern pasta production.

Benefits of Full Automation

The advantages of embracing a Fully Automated Macaroni Pasta Machine are multifaceted. This section explores the substantial benefits derived from automated processes, including heightened production speed, unparalleled precision, and consistent quality. Moreover, the environmental impact is scrutinized, with a focus on how energy-saving mechanisms contribute to resource efficiency and sustainability. Expert opinions from industry leaders reinforce the significance of these benefits in shaping the future of pasta manufacturing.

Case Studies

Real-world examples illuminate the transformative power of fully automated macaroni pasta machines. Case studies from prominent brands like Barilla, De Cecco, Creamette, San Giorgio, and Great Value provide tangible evidence of efficiency improvements and success stories. These brands serve as benchmarks, showcasing the diverse applications and adaptability of fully automated machines in different settings. The exploration of their experiences adds a practical dimension to the theoretical discourse.

Challenges and Solutions

Addressing potential challenges associated with fully automated pasta production, this section offers practical solutions to ensure the optimal performance of these machines. From technical glitches to operational hurdles, the focus is on providing actionable insights for overcoming obstacles. Emphasis is placed on the continuous improvement and adaptability of automated systems, offering a roadmap for businesses to navigate challenges successfully.

Market Trends and Innovations

Embarking on the exploration of current market trends for macaroni pasta machines, this section unveils the cutting-edge innovations driving the industry forward. We delve into the latest advancements in automation technology, shedding light on how these innovations impact efficiency. From smart features to enhanced user interfaces, the market is evolving to meet the demands of modern pasta manufacturers. Future projections and glimpses into the next wave of energy-saving solutions provide a forward-looking perspective for businesses seeking to stay at the forefront of technological advancements.

Considerations for Implementation

Guidance is provided on the crucial factors that businesses should consider when implementing a fully automated macaroni pasta machine. A comprehensive cost analysis, exploration of customization options, and scalability considerations for different production scales offer valuable insights. The seamless integration of these machines into existing processes is emphasized, ensuring businesses can harness the full potential of automation while maintaining operational efficiency.

Industry Impact and Sustainability

Analyzing the broader impact of fully automated macaroni pasta machines on the food industry, this section assesses the sustainability aspects and eco-friendly practices associated with automated pasta production. Insights are shared on how technology plays a pivotal role in shaping a more sustainable future for food manufacturing. Expert opinions and industry perspectives provide a comprehensive overview of the far-reaching implications of embracing fully automated solutions.

Conclusion

As we recap the key points surrounding fully automated macaroni pasta machines, it becomes evident that high-efficiency and energy-saving solutions are paramount in shaping the future of pasta production. The transformative power of automation has not only increased production speed and precision but has also contributed to a more sustainable and environmentally conscious industry.

In conclusion, businesses are encouraged to embrace the advancements in technology for a competitive edge in the modern food landscape. The Fully Automated Macaroni Pasta Machine represents a pivotal tool in achieving efficiency goals while contributing to a more sustainable and eco-friendly food industry. As we navigate the dynamic intersection of tradition and innovation, the journey into the future of pasta manufacturing continues, driven by the relentless pursuit of excellence and sustainability.

FAQs: Common Questions about Macaroni Pasta Machines

Q1: What sets fully automated macaroni pasta machines apart from traditional methods?

- Exploring the distinctive features and advantages of automation over traditional manufacturing.

- Highlighting how fully automated machines redefine efficiency and energy conservation.

Q2: How do these machines contribute to environmental sustainability?

- Discussing the eco-friendly aspects of fully automated macaroni pasta machines.

- Emphasizing the role of energy-saving mechanisms in reducing environmental impact.

Q3: Are there specific certifications or standards for ensuring the efficiency of these machines?

- Addressing the quality standards and certifications relevant to fully automated pasta production.

- Assuring businesses of the reliability and performance benchmarks.

Q4: Can businesses with varying production scales benefit from fully automated macaroni pasta machines?

- Offering insights into scalability options and customization features.

- Showcasing examples of businesses with different production scales successfully implementing automation.

Q5: How do automated systems handle the diversity of pasta shapes and sizes?

- Explaining the adaptability of fully automated machines in handling diverse pasta varieties.

- Providing technical insights into customization options for different pasta shapes.

Q6: What maintenance practices are essential for maximizing the lifespan of these machines?

- Offering a comprehensive guide to machine maintenance, including routine checks and troubleshooting.

- Providing practical tips for businesses to ensure the longevity of their investments.

Q7: How have renowned brands like Barilla, De Cecco, Creamette, San Giorgio, and Great Value embraced automation?

- Showcasing specific examples of these brands integrating fully automated macaroni pasta machines.

- Highlighting the positive outcomes and improvements witnessed by these industry leaders.

Q8: What role does automation play in the consistency of pasta quality?

- Discussing the precision and consistency achieved through automation.

- Citing examples of businesses that have achieved a higher standard of pasta quality through automated processes.