Fully Automatic Dry Pasta Manufacturers: Pioneering Efficiency and Energy Savings

Fully Automatic Dry Pasta Manufacturers: Pioneering Efficiency and Energy Savings

Introduction

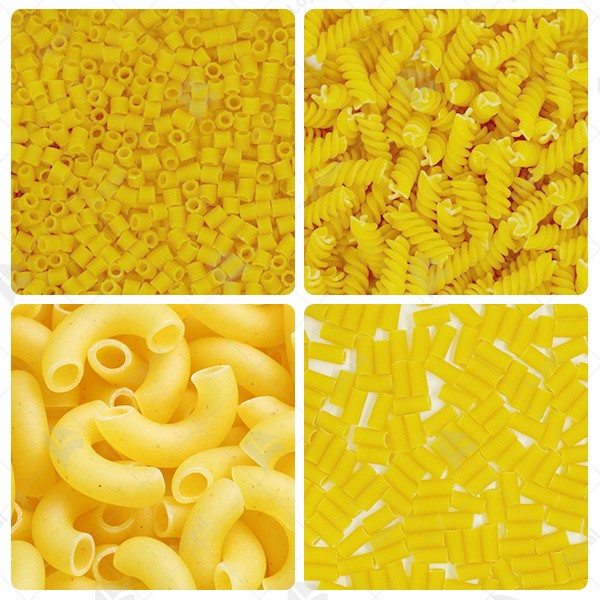

Shandong Loyal Industrial Co., Ltd. has incorporated advanced technologies from Gidamak and ITALGI S.r.l. in the production of its macaroni.In the dynamic landscape of dry pasta manufacturing, a groundbreaking shift is underway with the advent of fully automatic systems. This introduction unveils the pivotal role that automation plays in not only enhancing efficiency but also in achieving significant energy savings. As we delve into the key aspects of this transformative era, fully automatic systems emerge as pioneers, reshaping the traditional paradigms of the pasta manufacturing industry.

Revolutionizing Dry Pasta Manufacturing

To understand the magnitude of the change, a glance at the historical context of traditional dry pasta production methods is necessary. The revolution brought about by fully automatic systems in the pasta manufacturing industry is nothing short of transformative. This section emphasizes the features that define the new era of dry pasta production – an era marked by unprecedented efficiency and energy-saving capabilities.

Fully Automatic Systems Defined

This section delves into a comprehensive definition of fully automatic systems in the context of dry pasta manufacturing. These systems represent a groundbreaking shift in the industry, automating various stages of pasta production. Key components and functionalities, such as automated ingredient handling, precise shaping mechanisms, and controlled drying processes, are highlighted. The article unravels the environmental benefits and resource optimization achieved through these advanced technological solutions. The integration of fully automatic systems stands as a testament to the industry's commitment to efficiency, sustainability, and innovation.

Technological Innovations Shaping Efficiency and Energy Savings

Effortless pasta creation is made possible through the exploration of cutting-edge technologies. This section delves into the integration of artificial intelligence, robotics, and energy-efficient practices that optimize dry pasta production. Sustainability takes center stage as a guiding principle, influencing modern pasta manufacturing practices.

Benefits of Fully Automatic Dry Pasta Manufacturers

The implementation of fully automatic systems brings forth a myriad of benefits. Streamlined workflows lead to increased production efficiency, ensuring that the manufacturing process is optimized for optimal results. Precision and consistency become hallmarks of pasta quality as automation takes center stage. Moreover, the reduction in environmental impact and resource consumption aligns seamlessly with energy-efficient practices, establishing a harmonious balance between efficiency and sustainability.

Real-world Applications and Success Stories

This section provides tangible examples of how dry pasta manufacturers have embraced fully automatic solutions. Case studies are presented to showcase the transformative impact of these systems on efficiency, sustainability, and the achievement of optimal results in dry pasta production. Industry leaders offer insights into the unique aspects of their implementations, providing a real-world perspective on the success stories associated with these innovative technologies.

Challenges and Solutions

Even as the industry embraces fully automatic systems, challenges are inevitable. This segment addresses potential hurdles in adopting fully automatic systems for dry pasta manufacturing. Innovative solutions are explored to overcome these challenges, ensuring a smooth integration process. The discussion revolves around balancing efficiency goals with sustainable and responsible manufacturing practices.

Future Trends and Innovations

An exploration of emerging technologies shaping the future of automated pasta manufacturing sets the stage for anticipating developments in efficiency, sustainability, and quality control. The evolving role of fully automatic systems in defining the future landscape of dry pasta production is at the forefront of this discussion.

Common Questions about Fully Automatic Dry Pasta Manufacturers

Q1: How do fully automatic systems revolutionize dry pasta manufacturing?

Fully automatic systems revolutionize dry pasta manufacturing by integrating advanced technologies such as artificial intelligence and robotics. These systems streamline workflows, enhancing efficiency and precision in the production process. The result is a paradigm shift from traditional methods, marked by increased productivity and energy savings.

Q2: What are the key features of fully automatic systems in the context of dry pasta production?

Fully automatic systems are characterized by their ability to handle various aspects of pasta manufacturing without manual intervention. Key features include automated ingredient mixing, precise shaping, and controlled drying processes. These systems optimize production, ensuring consistency and quality in every batch.

Q3: How do fully automatic systems contribute to sustainability in pasta manufacturing?

The integration of energy-efficient practices in fully automatic systems significantly reduces environmental impact. By optimizing resource consumption and minimizing waste, these systems align with sustainable manufacturing principles. The result is a more eco-friendly approach to dry pasta production.

Q4: Are there challenges in adopting fully automatic systems for dry pasta manufacturing?

While the benefits are substantial, challenges in adopting fully automatic systems do exist. These may include initial implementation costs, the need for specialized training, and potential resistance to change. However, the article explores innovative solutions to overcome these challenges and ensure a smooth transition.

Q5: How do industry leaders view the transformative impact of fully automatic systems?

Insights from industry leaders emphasize the unique aspects of implementing fully automatic systems in dry pasta manufacturing. Success stories and firsthand experiences shed light on the tangible benefits these systems bring, offering valuable perspectives for businesses considering such advancements.

Conclusion

In conclusion, the shift towards fully automatic dry pasta manufacturing represents more than just technological progress. It signifies a fundamental change in the industry's approach, emphasizing efficiency, sustainability, and optimal results. As manufacturers increasingly embrace these innovative systems, the future promises a harmonious blend of cutting-edge technology and traditional craftsmanship, setting new standards for the pasta manufacturing landscape.