Optimizing Energy and Efficiency: The Full Automation of Macaroni Production Process

Optimizing Energy and Efficiency: The Full Automation of Macaroni Production Process

Introduction

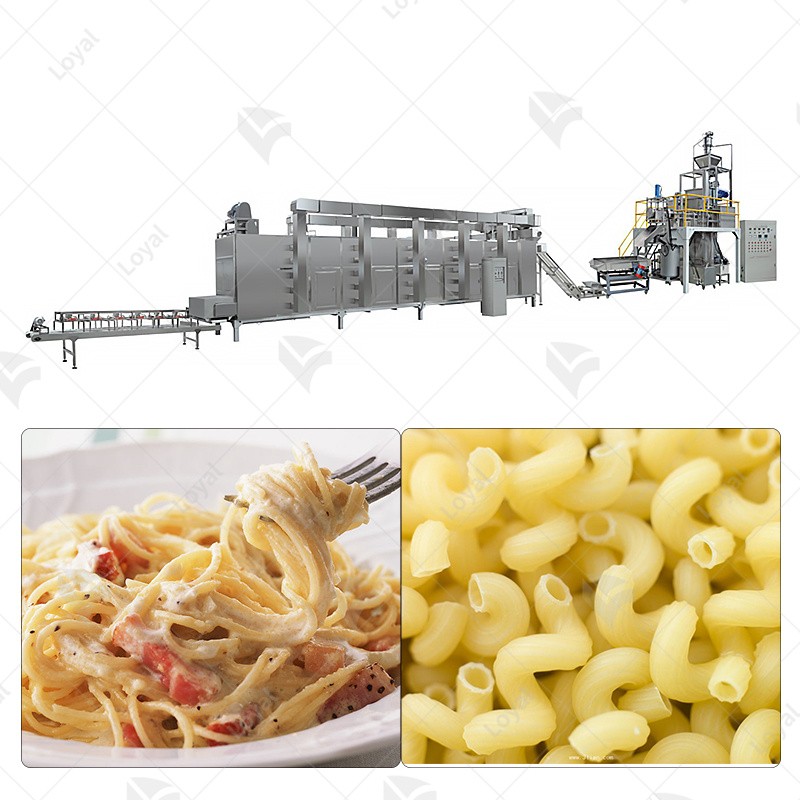

The Dry Pasta Production Line technology of Shandong Luoya Industrial Co., Ltd. has introduced advanced technologies from BUHLER and FEN .The macaroni production process is a pivotal aspect of the food industry, and the quest for optimizing energy and efficiency has led to the integration of full automation. This article explores the evolution of macaroni manufacturing, emphasizing the role of advanced technology in shaping the industry landscape.

Understanding the Macaroni Production Process

In delving into the intricacies of the macaroni production process, we compare traditional methods with the efficiency gains offered by automated approaches. Understanding and optimizing energy and efficiency play a crucial role in enhancing the overall production of macaroni.

Exploring Traditional Methods:

Understanding the roots of macaroni production involves examining traditional methods. From manual mixing and shaping to drying processes, traditional techniques provide a baseline for evaluating advancements in efficiency and energy consumption.

Efficiency Gains through Automation:

Automated approaches revolutionize macaroni production, introducing efficiency gains at every stage. The incorporation of machinery in mixing, extrusion, and drying processes reduces manual labor, speeds up production, and sets the stage for optimizing energy utilization.

Importance of Energy Optimization:

In the context of macaroni production, energy optimization becomes a critical factor. Analyzing the energy requirements of each stage allows for targeted improvements, ensuring that the overall process is not only efficient but also sustainable in terms of energy consumption.

Leveraging Full Automation for Energy Optimization

Cutting-edge technologies are driving the full automation of macaroni production. Real-time monitoring, adaptive controls, and innovative solutions contribute to increased energy efficiency. We explore how these advancements translate into energy savings and heightened efficiency in macaroni production.

Full automation enables real-time monitoring of key production parameters. Sensors and data analytics provide instant feedback, allowing for precise adjustments in real-time to optimize energy consumption and maintain consistent quality.

The integration of adaptive controls ensures that the macaroni production process adapts to variations, optimizing energy usage. These controls enable the system to respond dynamically to changing conditions, minimizing energy waste and maximizing efficiency.

Innovative Solutions for Energy Savings:

Innovations in automation include specific solutions designed to target energy savings. From energy-efficient motors to intelligent heat exchange systems, these technologies contribute to a more sustainable and cost-effective macaroni production process.

Precision Controls and Advanced Materials

In this section, we analyze the innovative features integrated into fully automated macaroni production systems. Emphasis is placed on precision controls and the incorporation of advanced materials, highlighting their role in optimizing energy consumption and fostering sustainability.

Precision controls in automated macaroni production systems ensure that each component operates with optimal efficiency. From extrusion speed to drying temperatures, precise control mechanisms contribute to energy optimization and product consistency.

The incorporation of advanced materials in macaroni production aligns with sustainability goals. From energy-efficient conveyor belts to eco-friendly packaging materials, the use of advanced materials reflects a commitment to reducing the environmental footprint of the entire production process.

Harmonizing precision controls with the use of advanced materials strikes a balance between efficiency and sustainability. This synergy ensures that energy is utilized judiciously while minimizing the environmental impact of the macaroni production process.

Sustainable Practices for Energy Conservation

Explore the strategies employed in fully automated macaroni production for energy conservation. Sustainable materials and energy-efficient technologies significantly reduce the environmental footprint. We uncover the positive outcomes and benefits associated with adopting these energy conservation practices in macaroni production.

Case Studies: Exemplifying Energy and Efficiency Optimization

Drawing lessons from industry leaders like La Molisana, Banza, Colavita, Garofalo, and Whole Foods 365 Everyday Value, we showcase how these companies have optimized energy and efficiency through full automation. Real-world examples provide insights and best practices for wider industry adoption.

Overcoming Challenges in Full Automation

Implementing a fully automated system often involves integrating diverse technologies. Overcoming the complexity of integrating these technologies seamlessly is a challenge. Solutions include comprehensive planning, phased implementation, and collaboration with experienced automation experts.

The shift to full automation may pose challenges in terms of the existing workforce adapting to new technologies. Training programs, upskilling initiatives, and transparent communication are essential for ensuring a smooth transition and garnering support from the workforce.

The initial investment required for fully automated systems can be significant. Companies may face financial challenges in funding the transition. Creative financing options, government incentives, and a clear ROI analysis are strategies to address this challenge.

Maintenance of advanced automated systems and potential downtime for upgrades or repairs can disrupt production schedules. Implementing predictive maintenance strategies and having contingency plans in place are essential to minimize downtime. With increased reliance on digital systems, data security becomes a priority. Addressing cybersecurity concerns through robust protocols, regular audits, and collaboration with cybersecurity experts is vital for protecting sensitive production data.

Future Trends: Advancements in Energy-Efficient Macaroni Production

Anticipate a widespread adoption of renewable energy sources such as solar and wind power in macaroni production facilities. This shift towards sustainability aligns with global efforts to reduce carbon footprints.

The Internet of Things (IoT) and data analytics will play a crucial role in optimizing energy usage. Smart sensors and data-driven insights will enable real-time adjustments, enhancing overall energy efficiency.

Innovations in packaging materials will focus on sustainability. Expect the use of advanced, eco-friendly materials that reduce environmental impact while maintaining product integrity.

Automation will continue to evolve towards greater efficiency. This includes the use of artificial intelligence for predictive maintenance, intelligent process optimization, and adaptive controls that respond dynamically to production demands.

The industry is likely to witness increased collaboration on a global scale to develop and share sustainable practices. This collaborative approach will contribute to a more sustainable and interconnected macaroni production ecosystem.

Conclusion

In conclusion, optimizing energy and efficiency in macaroni production through full automation is not just a technological upgrade but a strategic investment in a sustainable future. The benefits of enhanced energy optimization, efficiency, and reduced environmental impact are compelling reasons for businesses to embrace and invest in fully automated macaroni production systems. As we navigate the challenges and embrace future trends, the industry stands at the forefront of a transformative era, and proactive investment now will secure a competitive and sustainable future.