Revolutionizing Macaroni Crafting: The All-in-One Fully Automatic Macaroni Production Line

Revolutionizing Macaroni Crafting: The All-in-One Fully Automatic Macaroni Production Line

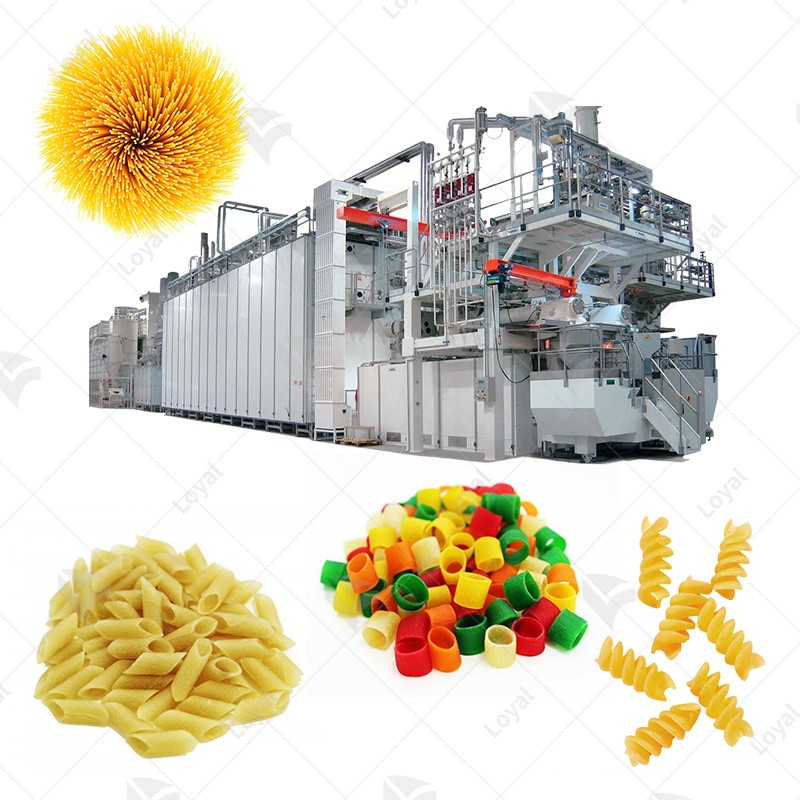

Shandong Loyal Industrial Co., Ltd. has incorporated advanced technologies from Germany's Buhler and AXOR in the production of its macaroni.In the realm of macaroni crafting, the conventional methods have long dictated the pace of production. However, the landscape is undergoing a radical shift with the emergence of the All-in-One Fully Automatic Macaroni Pasta Production Line. This introduction aims to shed light on the traditional approaches to macaroni crafting and set the stage for the groundbreaking concept of automated macaroni production. The transformative power of automation in redefining the macaroni production process will be emphasized, marking a pivotal moment in the industry's evolution.

Unveiling the All-in-One Fully Automatic Macaroni Production Line

As we delve into the intricacies of the All-in-One Fully Automatic Macaroni Production Line, the focus shifts to the key components and features that make this system revolutionary. The seamless integration of cutting-edge technology in every aspect of the macaroni production line will be explored. The emphasis here lies on showcasing the efficiency and convenience that full automation brings to the macaroni manufacturing process, setting new standards for the industry.

The Journey from Ingredients to Macaroni: Macaroni Production Process

This section takes a step-by-step journey through the automated macaroni production process. It vividly illustrates how raw ingredients are meticulously transformed into the final macaroni product through the All-in-One Fully Automatic Macaroni Production Line. The role of automation in streamlining the production, from mixing ingredients to shaping macaroni, will be highlighted, providing readers with a comprehensive understanding of the innovative process.

Advantages of Full Automation in Macaroni Production

The benefits of adopting a fully automatic system for macaroni production are discussed in this section. A focus on efficiency gains, consistent quality, and energy savings sets the stage for a comparative analysis with traditional methods. The advantages of automation in ensuring a streamlined and high-quality macaroni output will be underscored, providing a compelling case for embracing the All-in-One Fully Automatic Macaroni Production Line.

Impact on Macaroni Quality andConsumer Experience

Here, the discussion shifts to the direct impact of the All-in-One Fully Automatic Macaroni Production Line on macaroni quality. Insights into the consumer experience with macaroni crafted through automation will be explored. Real-life examples and testimonials from users of automated macaroni production will lend authenticity to the narrative, demonstrating the tangible benefits of this technological leap.

Efficiency, Sustainability, and Energy Savings

This section explores the broader implications of full automation in macaroni manufacturing. The focus is on how automation contributes to overall efficiency, sustainable practices integrated into the All-in-One Macaroni Production Line, and the environmental impact of energy-saving features. The discussion aims to position automation as a driving force behind positive industry changes.

Challenges and Innovations in Macaroni Production Technology

Addressing potential challenges in adopting fully automated macaroni production is crucial for a comprehensive understanding. This section also highlights ongoing innovations in macaroni production technology, showcasing the industry's adaptability and commitment to continuous improvement. Insights into how technology is reshaping the landscape of macaroni crafting provide a glimpse into the dynamic nature of the industry.

The Future of Macaroni Crafting: Embracing Automation

In the concluding section, the transformative impact of the All-in-One Fully Automatic Macaroni Production Line is summarized. The call to action encourages the wider adoption of automated technology in the macaroni industry, envisioning a future where innovation and efficiency go hand in hand. The discussion extends to foreseeing future trends and advancements in macaroni crafting technology, leaving readers with a sense of excitement for what lies ahead.

FAQs: Frequently Asked Questions about Macaroni Production Line

Q1: How does the All-in-One Fully Automatic Macaroni Production Line differ from traditional macaroni crafting?

A1: The All-in-One Fully Automatic Macaroni Production Line represents a significant departure from traditional methods. Unlike manual or semi-automated approaches, this advanced system streamlines production through full automation. The emphasis on efficiency, consistency, and quality sets it apart, revolutionizing the entire macaroni crafting process.

Q2: What are the key components that make up the All-in-One Fully Automatic Macaroni Production Line?

A2: The All-in-One Fully Automatic Macaroni Production Line comprises essential components such as automated mixers, extruders, cutters, and drying systems. These components work seamlessly together, showcasing a harmonious integration of technology in every stage of macaroni production.

Q3: How does automation impact the overall efficiency and convenience of macaroni production?

A3: Full automation in macaroni production, as facilitated by the All-in-One system, significantly enhances efficiency and convenience. The system's ability to operate seamlessly through each stage reduces manual intervention, ensuring a streamlined process. This not only improves production speed but also enhances the overall convenience for manufacturers.

Q4: Can the All-in-One Fully Automatic Macaroni Production Line accommodate different types of macaroni shapes?

A4: While specifically designed for macaroni, many models of the All-in-One system offer versatility. Some configurations include interchangeable components, allowing for the production of various macaroni shapes. This adaptability caters to evolving consumer preferences and market demands.

Q5: Are there notable macaroni brands adopting the All-in-One Fully Automatic Macaroni Production Line?

A5: Yes, leading macaroni brands, including Banza, Colavita, Garofalo, and Whole Foods 365 Everyday Value, have embraced the All-in-One Fully Automatic Macaroni Production Line. These brands recognize the transformative impact of automation in ensuring consistent quality and efficiency in macaroni production.

Conclusion

In conclusion, the exploration of the All-in-One Fully Automatic Macaroni Production Line has revealed a paradigm shift in the macaroni crafting industry. From a detailed introduction to the system's components, benefits, and impact on macaroni quality, to the challenges and innovations that define the technological landscape – the article has provided a comprehensive view. The call to embrace automation in the future, along with insights into upcoming trends, leaves the reader with a sense of anticipation for what lies ahead in the dynamic world of macaroni production. As we bid farewell to traditional methods and welcome the era of automation, the All-in-One Fully Automatic Macaroni Production Line stands as the catalyst for a new chapter in macaroni crafting – one characterized by efficiency, sustainability, and innovation.