Unveiling the Future: Full Automation in Pasta Manufacturing Machine for High Efficiency and Energy Conservation

Unveiling the Future: Full Automation in Pasta Manufacturing Machine for High Efficiency and Energy Conservation

Introduction

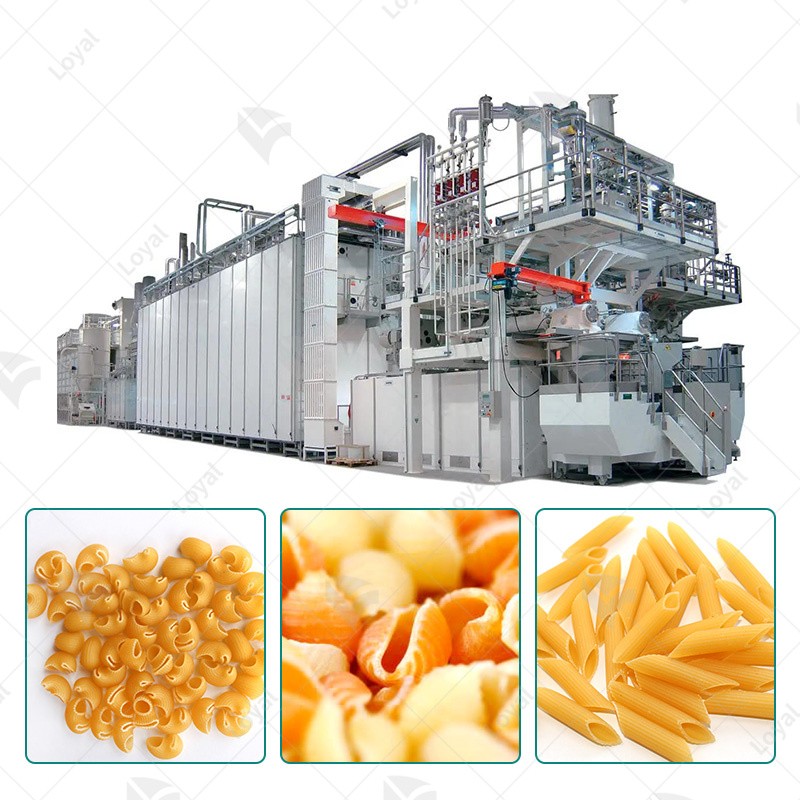

In the fast-evolving landscape of food production, the adoption of full automation in pasta manufacturing represents a pivotal shift. This introduction will define the term, emphasizing the significance of achieving high efficiency and energy conservation. We will explore how pasta manufacturing machines play a crucial role in shaping the future through full automation.The Macaroni Pasta Production Line technology of Shandong Luoya Industrial Co., Ltd. has introduced advanced technologies from TECHNOPAST and Lineapasta.

Understanding Full Automation in Pasta Manufacturing

Embark on an insightful journey into the core of fully automated pasta manufacturing machines. Delve into the components and cutting-edge technologies propelling full automation. Unveil the transformative impact of these systems on overall production efficiency, elucidating their vital role in shaping the future of the industry. This exploration will provide a comprehensive understanding of how full automation is reshaping traditional pasta manufacturing processes, from ingredient handling to the final packaging.

Technological Advancements: Paving the Way for Efficiency

Discover the technological marvels propelling the efficiency of fully automated pasta manufacturing machines. From real-time monitoring to adaptive controls, we'll explore the innovations contributing to increased efficiency and energy conservation. This section will delve into specific examples of technological advancements, such as AI-driven monitoring systems and adaptive control algorithms. By understanding these technologies, readers will grasp how they pave the way for a new era in pasta production, where efficiency and sustainability go hand in hand.

Innovative Features for Efficiency Optimization

Dive deep into the innovative features integrated into fully automated pasta manufacturing machines. Precision controls, advanced materials, and streamlined processes take center stage. Bold emphasis on how these features contribute to achieving optimal efficiency and energy conservation, citing expert perspectives to validate their significance in shaping the future of pasta production. Explore case studies of pasta manufacturing facilities that have successfully implemented these innovative features, showcasing their impact on efficiency, quality, and environmental sustainability.

Energy Conservation Strategies in Fully Automated Systems

This section will provide an in-depth look at strategies employed in fully automated pasta manufacturing for energy conservation. Sustainable materials, energy-efficient technologies, and their role in reducing environmental impact will be explored. Positive outcomes and benefits associated with adopting energy conservation practices in fully automated systems will be highlighted, contributing to shaping a sustainable future.

Case Studies: Successes in Implementing Full Automation

Examining real-world examples of companies that have successfully embraced full automation provides valuable insights. By showcasing how these companies, including renowned brands like Barilla, Banza, Colavita, and Garofalo, achieved high efficiency and substantial energy savings, this section offers practical lessons and best practices for the broader industry. These case studies serve as beacons of success, shaping the future of food production.

Overcoming Challenges: Navigating the Implementation of Full Automation

Identifying and addressing challenges is inherent in the pursuit of automated excellence. This section will analyze potential hurdles in implementing fully automated pasta manufacturing machines, providing innovative solutions and strategies to overcome them. Navigating these challenges is paramount for maximizing the benefits of automation, both in terms of efficiency and energy savings, and for shaping a seamless implementation future.

Future Trends: Advancements in Full Automation

Explore emerging trends and advancements in fully automated pasta manufacturing. Predictions for future developments in efficiency, energy conservation, and technological innovations will be discussed. The evolving landscape of the pasta manufacturing industry, with full automation as a key driver, will be outlined, shaping the future trends of the industry.

Conclusion

In conclusion, we recap key points on full automation, optimal efficiency, and energy conservation in pasta manufacturing. The transformative role of full automation in shaping the future of food production is highlighted. Businesses are encouraged to invest in full automation for a sustainable and efficient future, thereby unveiling the future of pasta manufacturing.

Common Questions About Pasta Manufacturing Machines

1.What challenges may arise in implementing fully automatic systems?

Discuss potential challenges in the adoption of fully automatic pasta manufacturing machines and provide insights into overcoming these hurdles.

2.Can smaller businesses benefit from fully automatic machines?

Address the scalability and adaptability of fully automatic systems, emphasizing how even smaller businesses can reap the rewards of enhanced efficiency and energy conservation.

3. How do these machines align with sustainability goals?

Delve into the sustainable practices and materials associated with fully automatic pasta manufacturing, underlining the positive environmental impact and alignment with broader sustainability objectives.

3. What trends can we expect in the future of pasta manufacturing?

Provide a glimpse into future trends and advancements in the field, illustrating how fully automatic pasta manufacturing machines will continue to drive progress in efficiency and energy conservation.

4. Are there government regulations or incentives supporting automation in food production?

Explore the regulatory landscape and potential incentives that encourage the adoption of automated systems in the food production industry, emphasizing the broader implications and support.

5. How can businesses transition to fully automated processes seamlessly?

Offer practical guidance for businesses looking to transition to fully automated pasta manufacturing, outlining steps, best practices, and considerations for a smooth implementation.