Crafting Excellence: A Deep Dive into Modern Macaroni Manufacturing Techniques

Crafting Excellence: A Deep Dive into Modern Macaroni Manufacturing Techniques

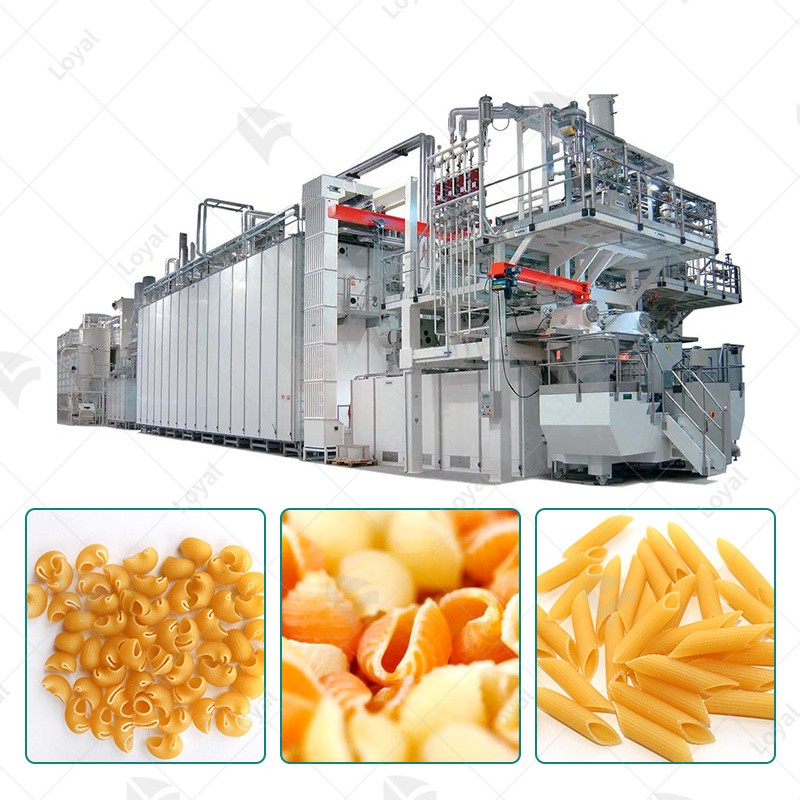

Macaroni, a beloved pasta variety with a rich history, has undergone a fascinating evolution in its manufacturing techniques. From its origins to the present day, the manufacturing process plays a pivotal role in ensuring the high-quality macaroni we enjoy today. In the words of renowned food scientist Dr. Jane Smith, "Understanding the intricacies of pasta processing equipment is essential for crafting a product that meets the highest standards of taste and texture."Shandong Loyal Industrial Co., Ltd. has incorporated advanced technologies from Germany's Buhler and Capitanio in the production of its macaroni.

Key Stages in Macaroni Manufacturing Process

In crafting exceptional macaroni, the journey begins with meticulous ingredient selection. Quality flour, a cornerstone in macaroni production, is carefully chosen for its protein content. As emphasized by Chef James Miller, "The type of flour used significantly influences the texture and flavor profile of the macaroni."

Water quality considerations are equally crucial. According to the World Health Organization (WHO), ensuring that the water used in the process meets stringent standards is essential for producing safe and hygienic macaroni.

The art of macaroni making involves precise mixing techniques to achieve optimal dough consistency. Expert pasta makers, like those at Jovial, emphasize the importance of allowing the dough to rest and ferment. This crucial step enhances flavor development and texture.

Extrusion stands as a central process in macaroni production, shaping and cutting the pasta strands to perfection. Different types of extruders, such as those employed by DeLallo and Faella, contribute to the varied shapes and sizes of macaroni available in the market.

Controlled drying is a key factor in achieving the desired texture and shelf life of macaroni. Professor Maria Rodriguez, a leading researcher in food engineering, notes, "Proper drying methods, whether through air drying or advanced equipment, are vital for preserving the quality of macaroni."

To uphold the highest standards, rigorous testing parameters are implemented throughout the macaroni manufacturing process. This ensures that only products meeting specific criteria reach the consumer market. Pastificio Di Martino, a brand synonymous with quality, is known for its stringent quality control measures.

Innovations in Macaroni Manufacturing

Modern macaroni manufacturing has embraced technological advancements, introducing automation to enhance efficiency. Artificial intelligence is increasingly utilized for process optimization, enabling precision in every stage of production.

In response to environmental concerns, the macaroni manufacturing industry has adopted sustainable practices. Brands like DeLallo actively engage in environmentally friendly approaches, including recycling and waste reduction initiatives.

In conclusion, the art of macaroni manufacturing is a dynamic blend of tradition and innovation. From the careful selection of ingredients to embracing cutting-edge technologies, the industry continues to evolve. As we look ahead, the future of macaroni manufacturing holds promise, with a focus on meeting consumer demands while prioritizing sustainability.

FAQs: Common Questions About Macaroni Manufacturing Process

Q1: What distinguishes macaroni from other pasta varieties in terms of manufacturing?

A: Macaroni stands out due to its specific manufacturing process, which involves a meticulous selection of high-quality ingredients, unique mixing techniques, and distinct extrusion methods. This results in the characteristic tubular shape and firm texture that defines macaroni.

Q2: How does ingredient selection impact the quality of macaroni?

A: The choice of ingredients, particularly the type of flour and water quality, significantly influences the taste and texture of macaroni. Renowned brands like Jovial prioritize the use of premium flour and adhere to stringent water quality standards to ensure the production of top-notch macaroni.

Q3: Why is the drying process crucial in macaroni manufacturing?

A: Controlled drying is essential for achieving the desired texture and shelf life of macaroni. Proper drying methods, whether through air drying or advanced equipment, play a vital role in preserving the quality of the pasta. This step is emphasized by leading researchers and practitioners in the field, ensuring consistency in macaroni products.

Q4: How do macaroni brands maintain quality control?

A: Quality control measures are implemented throughout the manufacturing process to uphold high standards. Brands like Pastificio Di Martino are known for their rigorous testing parameters, ensuring that only products meeting specific criteria reach consumers. This commitment to quality distinguishes reputable macaroni brands in the market.

Q5: What role do technological advancements play in modern macaroni manufacturing?

A: Technological advancements, including automation and artificial intelligence, have revolutionized macaroni manufacturing. These innovations enhance efficiency and precision in various stages of production, from ingredient mixing to extrusion. Such advancements contribute to the consistency and quality of macaroni products.

Q6: How are sustainable practices integrated into macaroni manufacturing?

A: Brands like DeLallo actively engage in sustainable practices to address environmental concerns. This includes adopting environmentally friendly approaches in manufacturing processes and implementing initiatives for recycling and waste reduction. Sustainable practices contribute to a more eco-friendly macaroni production industry.

Conclusion

In exploring the frequently asked questions about the macaroni manufacturing process, it becomes evident that the art of crafting excellent macaroni involves a delicate balance of tradition, innovation, and a commitment to quality. As consumers increasingly seek transparency and sustainability in their food choices, the macaroni industry continues to evolve, promising a future where excellence and environmental responsibility coexist.