Elevate Your Production Line with a Fully Automatic Macaroni Pasta Machine: Unparalleled Efficiency and Energy Savings

Elevate Your Production Line with a Fully Automatic Macaroni Pasta Machine: Unparalleled Efficiency and Energy Savings

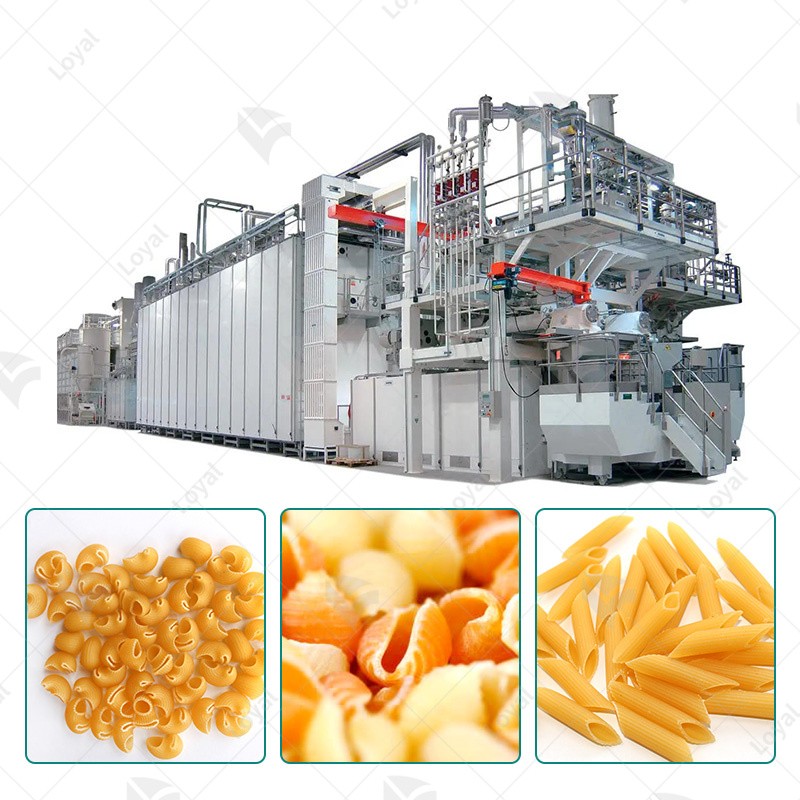

Shandong Loyal Industrial Co., Ltd. has incorporated advanced technologies from Buhler and Gidamak in the production of its macaroni.Efficient production in the food industry is paramount for meeting the demands of a rapidly growing market. In this era of modernization, the integration of cutting-edge technology becomes essential. This article introduces the transformative role of fully automatic pasta processing equipment in revolutionizing pasta production processes. As we delve into the significance of these machines, a captivating journey awaits to explore unparalleled efficiency and energy savings in the food manufacturing sector.

Unveiling Fully Automatic Macaroni Pasta Machines

Fully automatic macaroni pasta machines represent the pinnacle of technological innovation in the food machinery landscape. We embark on a comprehensive exploration of their features and capabilities, delving into the intricacies that set them apart. Highlighting the advancements in technology, we showcase how these machines stand at the forefront of efficiency, promising to elevate the entire pasta production experience. Real-world case studies bring to life successful implementations, offering a glimpse into the transformative power of these machines in modern production lines.

The Impact on Production Efficiency

This section carefully examines how fully automatic macaroni pasta machines streamline the production process. Through a comparative analysis of production rates and efficiency between manual and automatic systems, we aim to illustrate the substantial improvements brought about by these advanced machines. Real-world examples serve as tangible evidence of the positive impact on overall productivity, reinforcing the idea that efficiency is a cornerstone of modern pasta manufacturing.

Energy Conservation in Macaroni Production

Delving into the realm of sustainability, we explore the energy-saving features embedded in fully automatic macaroni pasta machines. Through insightful discussions and case studies, we demonstrate how these machines contribute to reduced energy consumption and environmental responsibility. Industry experts lend their insights, emphasizing the critical role of energy-efficient technologies in aligning food production with global sustainability goals.

Choosing the Right Fully Automatic Macaroni Pasta Machine

Selecting the right fully automatic macaroni pasta machine is a pivotal decision for any production line. This section provides a comprehensive guide, considering factors such as customization options, capacity, and adaptability to specific production needs. Expert recommendations serve as a valuable resource, empowering readers to make informed decisions that align with their unique requirements.

Integration into Existing Production Lines

Guidelines on seamlessly integrating fully automatic macaroni pasta machines into existing production processes take center stage in this section. Best practices are shared, ensuring a smooth transition and optimizing overall production efficiency. Success stories from businesses that have successfully incorporated these machines provide inspiration and practical insights for others considering this innovative leap.

Challenges and Solutions

While the benefits of fully automatic macaroni pasta machines are vast, addressing potential challenges is crucial. This section candidly explores common issues in adopting these machines and offers practical solutions and troubleshooting tips. Testimonials from industry professionals share their experiences in overcoming challenges, providing valuable lessons for those venturing into the realm of advanced pasta production.

Future Trends in Macaroni Pasta Machine Technology

As technology continually evolves, we gaze into the future of fully automatic macaroni pasta machines. This section explores emerging technologies and trends, predicting their evolution in enhancing efficiency and energy savings. Innovation takes center stage as we contemplate the shape of the future in macaroni production technology.

Case Studies: Success Stories of Efficient Production

Turning theory into practice, this section presents detailed case studies of businesses that have experienced significant improvements in efficiency and energy savings with fully automatic macaroni pasta machines. Interviews with industry leaders provide valuable insights into the transformative impact of these machines, while data-driven results showcase the measurable benefits achieved by adopting advanced technologies.

Conclusion

In conclusion, this guide has unveiled the extraordinary potential of fully automatic macaroni pasta machines in elevating production lines. The journey has explored unparalleled efficiency, energy savings, and sustainability in the modern food manufacturing sector. As we recap the key insights gained, we encourage food industry professionals to embrace innovation for improved efficiency and sustainability. The continuous advancements in macaroni pasta machine technology hold promise for a future where pasta production seamlessly blends tradition with cutting-edge efficiency.

FAQs: Common Questions about Macaroni Pasta Machines

Q1: What distinguishes fully automatic macaroni pasta machines from traditional manual methods?

- Explore the key features that set fully automatic machines apart, emphasizing efficiency and time savings.

- Reference industry experts' opinions on the transformative impact of automation in pasta production.

Q2: How do fully automatic macaroni pasta machines contribute to overall production efficiency?

- Detail the streamlined processes facilitated by these machines, improving production rates and reducing manual labor.

- Provide real-world examples of businesses that have witnessed significant efficiency gains after adopting automatic systems.

Q3: Are there specific models of fully automatic macaroni pasta machines that stand out in the market?

- Highlight renowned brands and models, discussing their features and contributions to the industry.

- Incorporate quotes from experts or customer reviews to add credibility to the recommendations.

Q4: Can these machines be customized to suit the unique needs of different production lines?

- Offer insights into the customization options available, ensuring adaptability to various production requirements.

- Share success stories of businesses achieving optimal results through tailored machine configurations.

Q5: How do fully automatic macaroni pasta machines contribute to energy conservation and sustainability?

- Discuss the eco-friendly features incorporated into these machines, emphasizing reduced energy consumption.

- Include statements from sustainability experts on the importance of adopting energy-efficient technologies in food production.

Q6: What challenges might businesses face when integrating fully automatic macaroni pasta machines into existing production lines?

- Address potential challenges such as training, system integration, and workflow adjustments.

- Provide practical solutions and expert advice to ease the transition and ensure a successful integration process.

Q7: Are there notable success stories of businesses experiencing efficiency improvements after adopting fully automatic macaroni pasta machines?

- Showcase case studies of businesses achieving tangible results in terms of increased productivity and reduced costs.

- Incorporate testimonials from industry leaders who have witnessed positive transformations in their production lines.

Q8: What future trends can we expect in the development of fully automatic macaroni pasta machine technology?

- Discuss emerging technologies and innovations that may shape the future of these machines.

- Include expert predictions on how technology will continue to advance, influencing the efficiency and capabilities of pasta production.

Q9: How can businesses stay informed about the latest developments in fully automatic macaroni pasta machine technology?

- Recommend reliable sources for staying updated, such as industry publications, conferences, and online forums.

- Encourage businesses to actively engage with the community and share their experiences for mutual learning.

Q10: Are there any notable pasta brands produced using fully automatic macaroni pasta machines?

- Highlight renowned pasta brands such as La Molisana, Banza, Colavita, Garofalo, and Great Value.

- Discuss how these brands leverage advanced machinery to ensure high-quality pasta production.