Fully Automated Equipment Redefining Pasta Production The Ultimate Guide

Fully Automated Equipment Redefining Pasta Production The Ultimate Guide

Introduction

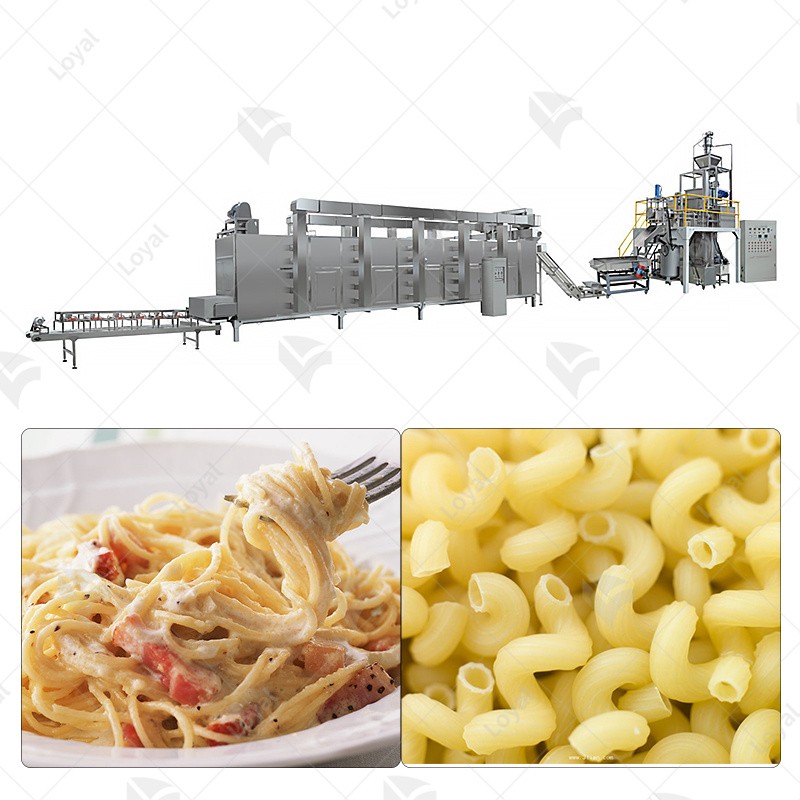

Shandong Loyal Industrial Co., Ltd. has incorporated advanced technologies from Unifood Machinery and Tecalit in the production of its macaroni. The landscape of pasta production has evolved significantly throughout history, adapting to the increasing demand for sustainable and efficient solutions. This article delves into the imperative shift towards sustainability in manufacturing, introducing fully automatic equipment Macaroni Pasta Production Line as a key player in achieving sustainability goals for pasta production. The focus is on unveiling sustainable excellence through the integration of cutting-edge technology.

Technological Advancements in Fully Automatic Equipment

In this section, we explore the cutting-edge features of fully automatic equipment designed to revolutionize pasta production. These advancements not only enhance efficiency but also contribute to the industry's sustainability goals. Precision engineering is emphasized, ensuring that the quality of pasta meets and exceeds industry standards. Additionally, the integration of energy-efficient practices is discussed, highlighting the positive environmental impact and cost savings associated with these innovations.

Case Studies: Exemplifying Sustainable Excellence

Company X stands as a shining example of sustainable excellence in pasta production through the adoption of fully automatic equipment. By integrating cutting-edge technology into their manufacturing processes, they achieved a remarkable increase in efficiency. The implementation not only streamlined their production line but also resulted in substantial energy savings, aligning with global sustainability goals.

Enhanced Efficiency: The fully automatic equipment optimized each stage of pasta production, reducing processing time and increasing overall output.Cost Savings: Energy-efficient practices led to a notable decrease in operational costs, showcasing the economic benefits of sustainable technology.Consistent Quality: Precision engineering ensured that every batch of pasta met the highest quality standards, enhancing the company's reputation for excellence.

Company Y's commitment to sustainable practices has had a profound impact on the pasta production industry. Their focus on environmentally conscious manufacturing has set new standards and inspired other manufacturers to follow suit. By embracing fully automatic equipment with an emphasis on sustainability, Company Y has catalyzed positive changes throughout the industry.

Increased Awareness: Company Y's success has heightened awareness of the benefits of sustainable practices, encouraging other manufacturers to explore similar approaches.

Regulatory Influence: The industry has witnessed increased regulatory focus on sustainable manufacturing, driven in part by the pioneering efforts of Company Y.

Consumer Preference: With a growing emphasis on environmental responsibility, consumers now prefer pasta products manufactured using sustainable methods, further driving industry-wide changes.

Future Trends: Advancing Sustainability in Pasta Production

The future of sustainability in pasta production is shaped by emerging technologies that prioritize eco-friendly practices. Automation is evolving to encompass even more energy-efficient processes, waste reduction strategies, and precision-enhancing innovations. These advancements not only address current challenges but also anticipate the industry's evolving needs.

Smart Automation: Predictive analytics and machine learning will be integrated into fully automatic equipment, allowing for proactive maintenance and optimizing energy consumption.

Circular Economy Practices: Manufacturers will increasingly adopt circular economy principles, focusing on reducing waste, recycling, and repurposing by-products.

Precision Agriculture: The supply chain will see advancements in precision agriculture techniques, ensuring sustainability from raw material production to the final pasta product.

Top manufacturers are expected to drive innovations that redefine sustainability in pasta production. Their ongoing commitment to environmental responsibility will lead to breakthroughs in efficiency, resource utilization, and waste reduction.

Carbon-Neutral Production Lines: Manufacturers will aim for carbon-neutral operations, leveraging renewable energy sources and offsetting emissions.

Closed-Loop Water Systems: Water conservation will be prioritized through the implementation of closed-loop systems, reducing overall water consumption.

Packaging Innovations: Sustainable packaging solutions, including biodegradable materials and eco-friendly designs, will become standard in the industry.

Conclusion

Summarizing the key points, we recap the essence of sustainable excellence in pasta production achieved through fully automatic equipment. The conclusion emphasizes the importance of adopting such technology for long-term industry growth. Encouraging businesses to embrace fully automatic equipment, the article concludes by highlighting the path forward—a future where sustainable practices are integral to efficient and environmentally conscious pasta production.

FAQs: Common Questions About Pasta Production

1. How does fully automatic equipment redefine pasta production?

Fully automatic equipment revolutionizes pasta production by integrating cutting-edge technology, enhancing efficiency, ensuring precision, and contributing to sustainable practices. It streamlines processes, resulting in high-quality pasta while meeting industry standards.

2. What are the key technological advancements in fully automatic equipment?

Cutting-edge features include advanced automation, precision engineering, and energy-efficient practices. These advancements not only improve efficiency but also align with sustainability goals, making fully automatic equipment a cornerstone in the evolution of pasta production.

3. How do energy-efficient practices benefit pasta production?

Energy-efficient practices integrated into fully automatic equipment contribute to environmental sustainability by reducing energy consumption. This not only aligns with global environmental initiatives but also results in cost savings for manufacturers.

4. Can you provide examples of successful implementation of fully automatic equipment?

Certainly. Case studies, such as Company X's successful adoption of fully automatic equipment, showcase improved efficiency and positive outcomes. Industry impact studies, like that of Company Y, demonstrate how sustainable practices positively influence the pasta production landscape.

5. What emerging technologies are shaping sustainability in pasta production?

Upcoming technologies include innovations in automation, precision engineering, and sustainable practices. These trends are anticipated to further enhance sustainability in pasta production, offering a glimpse into the industry's future.