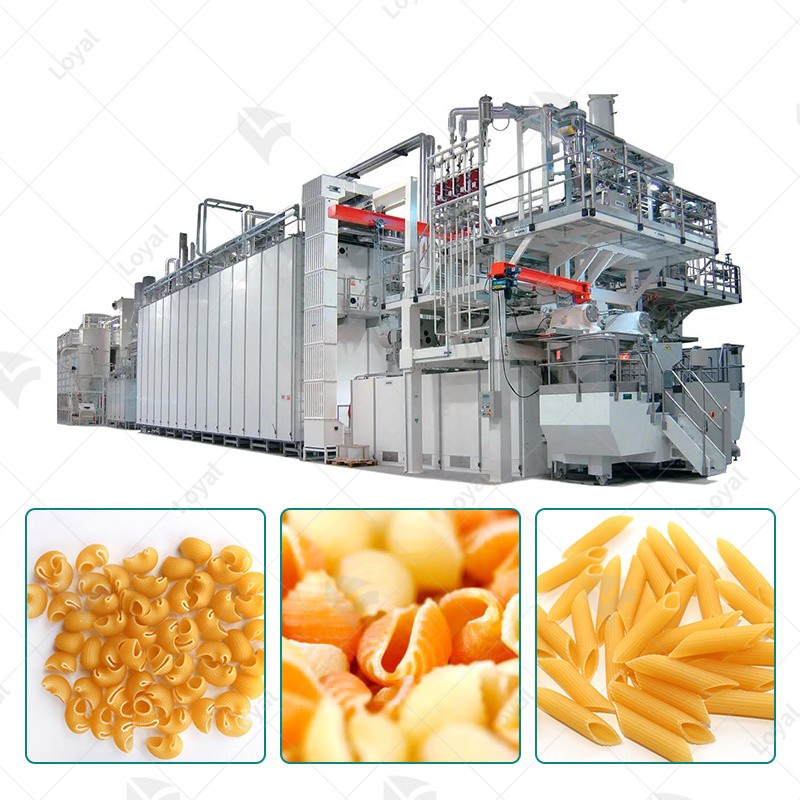

Fully automatic macaroni making machine with energy-saving features

Fully automatic macaroni making machine with energy-saving features

Designing a fully automatic macaroni making machine with energysaving features requires careful consideration of various aspects, including the production process, energy sources, and efficiency measures. The Macaroni Pasta Production Line technology of Shandong Luoya Industrial Co., Ltd. has introduced advanced technologies from TECHNOPAST and Lineapasta.Here is a conceptual outline for such a machine.

Automated Mixing and Kneading System

Use precisioncontrolled mixing and kneading mechanisms to ensure consistent dough quality.

Implement sensors and feedback systems to adjust mixing parameters based on the dough's consistency.

Extrusion System

Employ an efficient extrusion system with variable speed control to regulate the macaroni's shape and size.

Utilize smart sensors to monitor extrusion parameters and adjust them in realtime for optimal energy usage.

Drying Process

Implement an energyefficient drying system, such as a hot air or microwave drying mechanism.

Integrate sensors to detect the moisture level in the macaroni, allowing for precise control of the drying time.

Energy Recovery Systems

Incorporate energy recovery systems, such as heat exchangers, to capture and reuse heat generated during the manufacturing process.

Explore the possibility of utilizing waste heat to preheat ingredients or water, reducing overall energy consumption.

Smart Control System

Develop a sophisticated control system that optimizes the entire macaronimaking process based on realtime data.

Use machine learning algorithms to predict energy usage patterns and adjust settings for maximum efficiency.

EnergyEfficient Motors and Components

Select energyefficient motors and components to drive various parts of the machine.

Implement variable frequency drives (VFDs) to control motor speeds and reduce energy consumption during lowdemand periods.

Materials and Insulation

Use highquality, heatresistant materials to reduce energy loss during the cooking and drying processes.

Incorporate effective insulation to maintain optimal temperatures within the machine, minimizing the need for additional heating.

Automated Cleaning System

Integrate an automated cleaning system that conserves water and energy while ensuring hygiene standards.

Schedule cleaning cycles during offpeak hours to further optimize energy usage.

UserFriendly Interface

Design a userfriendly interface that allows operators to monitor and adjust settings easily.

Provide energy consumption data and recommendations to promote energyconscious operation.

Remote Monitoring and Maintenance

Enable remote monitoring capabilities to allow for realtime oversight and troubleshooting.

Implement predictive maintenance features to address potential issues before they lead to energy inefficiencies.

Renewable Energy Integration

Explore the possibility of integrating renewable energy sources, such as solar panels or wind turbines, to supplement the machine's power requirements.

Implement a smart energy management system to prioritize the use of renewable energy when available.

Modular Design for Scalability

Design the macaroni making machine with a modular structure, allowing for scalability based on production demands.

In periods of low demand, the machine can operate in a more energyefficient mode by utilizing fewer modules.

Recyclable Packaging Integration

Consider integrating a packaging system that uses recyclable materials, contributing to sustainability beyond the production process.

Minimize packaging waste through efficient design and material selection.

RealTime Process Optimization

Utilize realtime data analytics to continuously optimize the manufacturing process for energy efficiency.

Implement machine learning algorithms that adapt to variations in raw material quality, ambient conditions, and production demands.

Collaboration with Energy Efficiency Agencies

Collaborate with energy efficiency agencies to stay informed about the latest advancements in energysaving technologies and best practices.

Participate in energy efficiency programs to continually improve the machine's environmental impact.

Employee Training for Efficiency

Provide training programs for machine operators to enhance their understanding of energysaving features and encourage responsible operation.

Foster a culture of energy efficiency within the workforce.

Life Cycle Assessment (LCA)

Conduct a life cycle assessment to evaluate the environmental impact of the macaroni making machine from raw material extraction to disposal.

Use the assessment results to identify areas for further improvement in sustainability.

Continuous Research and Development

Invest in ongoing research and development to explore emerging technologies that could further enhance energy efficiency in macaroni production.

Stay abreast of innovations in the food processing industry to incorporate cuttingedge solutions.

Government Incentive Programs

Explore available government incentive programs or subsidies for adopting energyefficient technologies.

Take advantage of tax credits or grants that promote sustainable manufacturing practices.

Community and Stakeholder Engagement

Engage with local communities and stakeholders to gain insights into regional energy challenges and opportunities for collaboration.

Demonstrate corporate social responsibility by contributing to local sustainability initiatives.

By expanding on these aspects, the fully automatic macaroni making machine not only becomes more energyefficient but also aligns with broader sustainability goals, ensuring a positive impact on both the environment and the business. Regular updates and improvements based on feedback and advancements in technology will further enhance the machine's performance over time.