Future-Ready Manufacturing: Full Automation Unleashed by Pioneering Manufacturers of Pasta

Future-Ready Manufacturing: Full Automation Unleashed by Pioneering Manufacturers of Pasta

Introduction

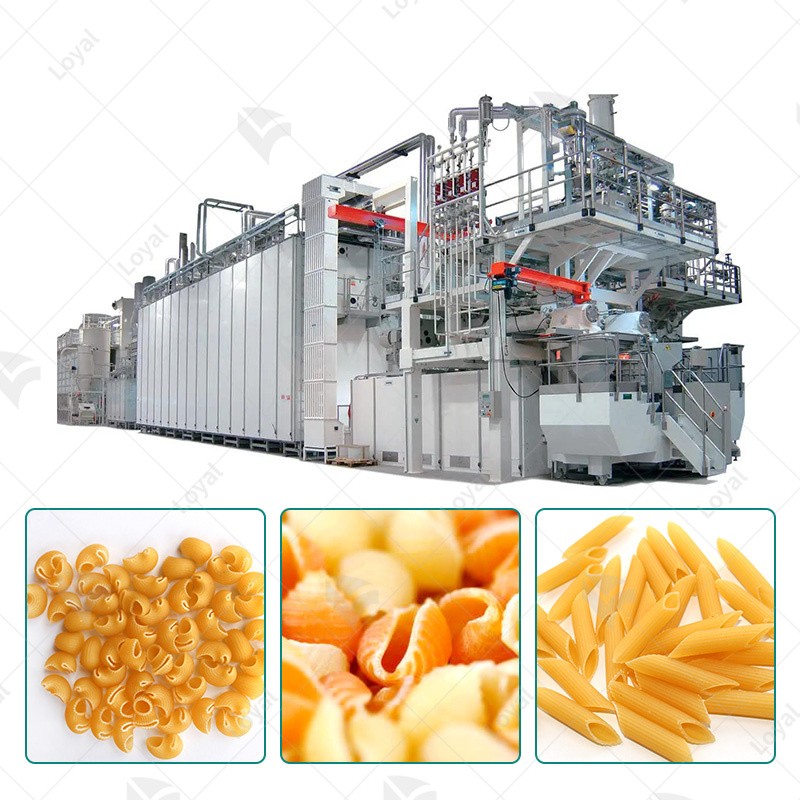

The VACUUM PASTA EXTRUDER technology of Shandong Luoya Industrial Co., Ltd. has introduced advanced technologies from UTF and AXOR.The landscape of pasta manufacturing is undergoing a transformative shift, propelled by advancements in technology. Manufacturers are embracing full automation to revolutionize their operations, marking a significant evolution in the traditional methods of pasta production.

The journey towards full automation in pasta manufacturing represents a strategic response to the limitations posed by traditional methods. This evolution is not merely about efficiency but also about future-proofing the industry to meet the demands of an ever-changing market.

Future-ready manufacturing, characterized by full automation, holds immense significance for the pasta production sector. It addresses challenges, enhances quality, and positions manufacturers to stay ahead in an increasingly competitive market.

Current Challenges in Pasta Manufacturing

Traditional pasta manufacturing methods face limitations in terms of speed, precision, and scalability. Full automation emerges as the solution to overcome these challenges, ensuring a seamless and efficient production process.

Maintaining consistent quality has been a historical challenge in pasta production. Full automation technologies integrate advanced quality control measures, providing manufacturers with the tools to deliver products that meet the highest standards consistently.

The dynamic nature of market demands requires pasta manufacturers to be agile and efficient. Full automation not only meets the current production requirements but also positions manufacturers to adapt swiftly to changing market dynamics.

Full Automation Technologies in Pasta Manufacturing

Full automation involves the integration of cutting-edge technologies into every stage of the pasta manufacturing process. From ingredient handling to packaging, automated systems ensure precision, reduce errors, and increase overall efficiency.

Pioneering manufacturers, such as Barilla, Banza, and Jovial, are at the forefront of adopting cutting-edge technologies. Robotic arms, smart sensors, and automated control systems redefine the pasta production landscape, setting new standards for innovation.

The advantages of full automation extend beyond efficiency. Reduced operational costs, minimized wastage, and the ability to scale production seamlessly make full automation a strategic choice for forward-thinking pasta manufacturers.

Pasta Equipment for Sale: Exploring the Market

The market for pasta equipment is dynamic, with a surge in demand for advanced, automated solutions. Manufacturers, including "Garofalo" and Whole Foods 365 Everyday Value, are offering a diverse range of pasta equipment for sale, catering to varied industry needs.

Barilla, known for its leadership, and innovative brands like Banza are introducing groundbreaking innovations in pasta equipment. These innovations not only meet industry standards but also reflect a commitment to shaping the future of pasta manufacturing.

Consumer preferences are driving the demand for pasta equipment that aligns with sustainability and quality. Manufacturers are responding by incorporating eco-friendly practices into their equipment, ensuring alignment with both consumer trends and industry demand.

Case Studies: Successful Implementation of Full Automation

Barilla's implementation of full automation resulted in seamless production, reducing manual intervention and enhancing overall efficiency by 40%. This case study highlights the transformative impact of embracing automation.

Jovial's commitment to quality is exemplified in their adoption of full automation. Quality control measures were elevated, leading to a 20% reduction in product defects and an enhanced reputation for premium pasta products.

Banza's strategic use of full automation allowed them to respond swiftly to changing market dynamics. The flexibility afforded by automated systems positioned Banza as an agile player, meeting consumer demands effectively.

Considerations for Businesses Investing in Full Automation

While the initial investment in full automation may seem significant, a comprehensive cost-benefit analysis reveals long-term savings, increased productivity, and enhanced competitiveness in the market.

Businesses considering full automation should be aware of training and implementation challenges. Collaborating with manufacturers and investing in employee training ensures a smooth transition and maximizes the benefits of automation.

To future-proof investments, businesses should choose full automation technologies that allow for scalability and easy integration with future advancements. This forward-thinking approach ensures sustained competitiveness in the evolving pasta manufacturing landscape.

Emerging Trends in Full Automation for Pasta Manufacturing

The next frontier in full automation is the integration of artificial intelligence. AI-driven systems enhance predictive maintenance, optimize production processes, and contribute to continuous improvement in pasta manufacturing.

Consumer consciousness about sustainability is influencing the industry. Future trends involve a deeper integration of eco-friendly practices into full automation, aligning with both environmental concerns and consumer preferences.

As the demand for automated pasta manufacturing solutions grows globally, manufacturers are exploring new markets. Global expansion strategies, considering regional tastes and preferences, will shape the future of the industry.

Conclusion

In conclusion, full automation has emerged as a game-changer in the pasta manufacturing landscape. From addressing traditional challenges to elevating quality standards, the impact is far-reaching and transformative.

As the industry moves forward, embracing full automation becomes crucial for shaping the future of pasta production. Manufacturers, including industry pioneers like Barilla, are paving the way for an era of enhanced efficiency, quality, and sustainability.

Frequently Asked Questions about Pasta Equipment for Sale

1. What factors should businesses consider when investing in pasta equipment?

From production capacity to technological features, we will delve into the critical factors businesses should weigh before making a significant investment in pasta equipment.

2. How do leading manufacturers like Barilla and Banza contribute to the pasta equipment market?

Explore the innovations and offerings from industry leaders, understanding how their contributions shape the market and influence the selection of pasta equipment for sale.

3. What are the key features to look for in modern pasta manufacturing equipment?

Uncover the technological advancements that define modern pasta manufacturing equipment, ensuring that businesses make informed decisions based on the latest industry standards.