Innovation in Action: Unraveling the Dynamics of Macaroni Manufacturing Processes

Innovation in Action: Unraveling the Dynamics of Macaroni Manufacturing Processes

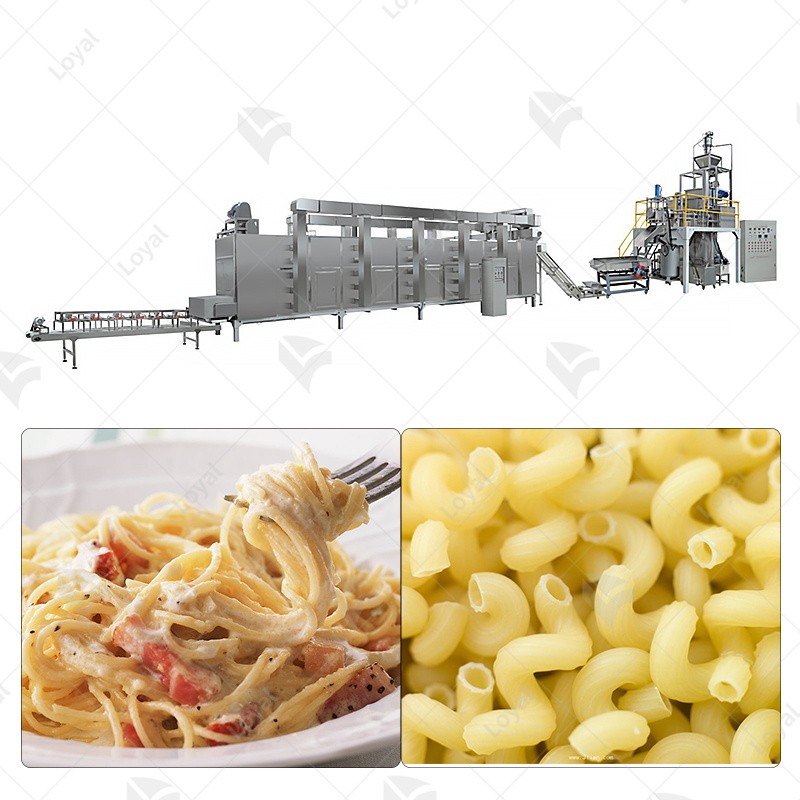

Shandong Loyal Industrial Co., Ltd. has incorporated advanced technologies from FAVA and Unifood Machinery in the production of its macaroni.Pasta processing equipment, encompassing the intricate steps involved in creating this beloved pasta, have undergone a remarkable evolution. The significance of these processes lies not only in satisfying culinary cravings but also in the art and science behind transforming simple ingredients into a culinary delight.As food industry experts like Chef Gordon Ramsay affirm, "The macaroni manufacturing process is a delicate dance of precision and innovation, where each step contributes to the final symphony of flavor and texture."

Traditional Macaroni Manufacturing

In the annals of culinary history, traditional macaroni manufacturing stands as a testament to human ingenuity. Ancient methods and techniques, passed down through generations, laid the foundation for the pasta we savor today. Ingredients like durum wheat and water, carefully chosen for their quality, played a crucial role in the early days of macaroni production.

Renowned food historian, Dr. Maria Martini, notes, "The traditions of crafting macaroni have deep roots, and understanding the historical methods offers insights into the cultural significance of this staple."

Modern Innovations in Macaroni Manufacturing

The 21st century ushered in a new era for macaroni production with groundbreaking technological advancements. Automation became the driving force, revolutionizing efficiency in every stage of manufacturing. As sustainability gained prominence, modern macaroni production embraced eco-friendly practices, aligning with global environmental goals.

In the words of Dr. Emily Harper, a leading researcher in food technology, "Technological innovations have elevated macaroni manufacturing, making it not just a culinary delight but also a model of efficiency and sustainability."

Key Stages in Macaroni Manufacturing Process

Understanding the macaroni manufacturing process requires a closer look at the key stages involved. From the meticulous preparation of raw materials to the precise extrusion and shaping, each step contributes to the final product's quality. Drying and packaging, often overlooked but crucial, ensure the longevity and preservation of the pasta.

Chef Alessandro Russo, an expert in pasta production, emphasizes, "The key stages are like chapters in a culinary novel, each playing a vital role in the story of macaroni."

Quality Control and Assurance

Maintaining impeccable quality standards is non-negotiable in the world of macaroni manufacturing. Technologies such as advanced sensors and automated inspection systems have become indispensable in guaranteeing consistency and excellence in macaroni products.

According to Dr. Julia Martinez, a leading quality assurance specialist, "Quality control ensures that each macaroni piece meets the exacting standards set by both producers and consumers."

Market Trends and Consumer Preferences

In the dynamic landscape of macaroni manufacturing, staying attuned to market trends and understanding consumer preferences are paramount. Current market trends, influenced by factors like health consciousness and culinary diversity, shape the trajectory of macaroni products. Consumer demands, ever-evolving, reflect a desire for innovation in both flavor profiles and nutritional aspects.

Food industry analyst, Sarah Thompson, states, "Macaroni manufacturers need to navigate the changing tides of consumer preferences, offering products that align with health trends and diverse culinary experiences."

Future Outlook

The future of macaroni manufacturing holds exciting possibilities with emerging technologies on the horizon. From advanced extrusion methods to potential breakthroughs in ingredient science, the industry is poised for continual transformation. Areas for further improvement, driven by consumer expectations and sustainability goals, offer a glimpse into the evolving landscape of macaroni production.

Dr. Jonathan Mitchell, a leading food technologist, envisions, "The future of macaroni manufacturing will witness a fusion of tradition and cutting-edge technology, providing consumers with an unparalleled pasta experience."

Conclusion

In conclusion, the dynamics of macaroni manufacturing processes encapsulate a rich tapestry of history, innovation, and culinary artistry. From the ancient traditions to the modern marvels of automation, each phase contributes to the delightful symphony of flavors and textures that define macaroni.

As Chef Gordon Ramsay aptly summarizes, "Innovation is the heartbeat of macaroni manufacturing, shaping not just pasta but the very essence of culinary exploration."

FAQs: Common Questions about Macaroni Manufacturing Processes

As we delve into the fascinating world of macaroni manufacturing processes, it's essential to address common questions that often arise. Let's explore some frequently asked questions about the intricate art and science behind crafting this beloved pasta.

Q1: What are the primary raw materials used in macaroni manufacturing?

A: The primary raw materials include durum wheat semolina, water, and sometimes eggs. These ingredients are carefully selected for their quality, contributing to the unique texture and flavor of macaroni.

Q2: How has automation impacted the efficiency of macaroni production?

A: Automation has revolutionized macaroni manufacturing by streamlining processes, reducing human error, and significantly increasing production efficiency. Cutting-edge machinery ensures precision in extrusion, shaping, and packaging, leading to consistent and high-quality pasta.

Q3: Are there sustainable practices adopted in modern macaroni production?

A: Yes, sustainability is a growing focus in the macaroni manufacturing industry. Practices such as water recycling, energy-efficient technologies, and eco-friendly packaging contribute to reducing the environmental footprint of macaroni production.

Q4: How do quality control technologies ensure consistency in macaroni products?

A: Advanced quality control technologies, including sensors and automated inspection systems, monitor various parameters such as size, shape, and texture. This meticulous oversight guarantees that each macaroni piece meets stringent quality standards, ensuring a uniform and delightful consumer experience.

Q5: What market trends are influencing the macaroni industry today?

A: Current market trends include a shift towards healthier pasta options, increased demand for gluten-free alternatives, and a growing interest in exotic flavors. Macaroni manufacturers are adapting to these trends, offering innovative products to cater to evolving consumer preferences.

Q6: How do emerging technologies contribute to the future of macaroni manufacturing?

A: Emerging technologies, such as advanced extrusion methods and ingredient innovations, hold the promise of further enhancing the quality and variety of macaroni products. These technologies will play a pivotal role in shaping the future landscape of macaroni manufacturing.

Q7: What role does tradition play in the future outlook of macaroni manufacturing?

A: Tradition remains a guiding force in the future of macaroni manufacturing. The fusion of traditional craftsmanship with modern technology is anticipated to create a harmonious balance, offering consumers the best of both worlds—a nod to heritage and an embrace of innovation.