Revolutionizing Efficiency: The Ultimate Shortcut for Manufacturing Success in Pasta Production

Revolutionizing Efficiency: The Ultimate Shortcut for Manufacturing Success in Pasta Production

Setting the Stage: Evolution of Pasta Production

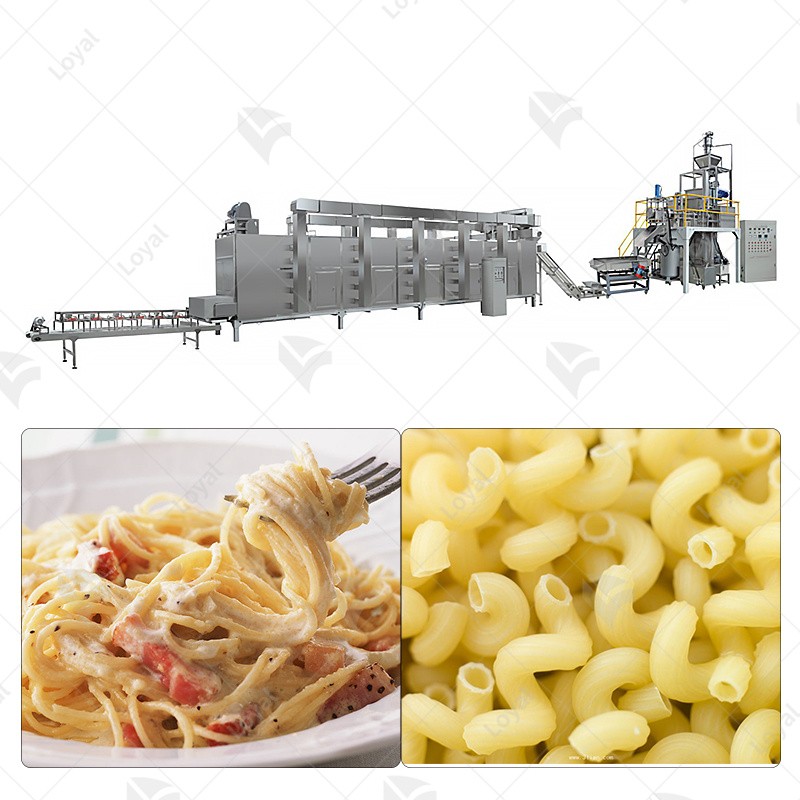

The evolution of pasta production has been marked by centuries of traditional craftsmanship, transitioning into the modern era of advanced technology. Today, the industry faces the challenge of meeting increasing demands while maintaining the quality and efficiency expected by consumers.Shandong Loyal Industrial Co., Ltd. has incorporated advanced technologies from Buhler and Gidamak in the production of its short-cut pasta production line.

The Concept of a "Shortcut for Manufacturing"

In the context of pasta production, the concept of a "shortcut for manufacturing" refers to innovative approaches that significantly enhance efficiency and success. This article explores how fully automated processes serve as the ultimate shortcut, revolutionizing traditional methods and setting new standards for success in the pasta manufacturing sector.

Fully Automated Processes in Pasta Production

Embracing Full Automation

The adoption of fully automated processes in pasta production represents a paradigm shift in manufacturing. Embracing automation involves integrating advanced machinery into every stage of the production line, from mixing and shaping to drying and packaging. This comprehensive automation ensures precision and consistency, optimizing the entire manufacturing process.

Navigating the Manufacturing Landscape

Navigating the manufacturing landscape involves identifying key challenges and bottlenecks within traditional pasta production. By strategically implementing automated solutions, manufacturers can streamline their processes, overcome obstacles, and achieve a more efficient and cost-effective production flow.

The Ultimate Shortcut: Achieving Success in Pasta Manufacturing

Efficiency as the Key Success Metric

Efficiency stands as the cornerstone of success in pasta manufacturing. As the industry adopts the ultimate shortcut of fully automated processes, efficiency becomes a measurable metric, encompassing increased production speed, resource optimization, and consistent product quality.

Benefits of Implementing a "Shortcut for Manufacturing"

Implementing a "shortcut for manufacturing" through full automation yields numerous benefits. From a reduction in operational costs to enhanced product quality, manufacturers experience increased competitiveness in the market. The shortcut of automation proves to be a catalyst for success, offering tangible advantages in a dynamic industry.

Case Studies: Success Stories in Revolutionizing Pasta Production

Companies Leading the Way

Pioneering companies such as Barilla, De Cecco, Creamette, San Giorgio, and Great Value have embraced fully automated processes, revolutionizing their pasta production. These industry leaders serve as exemplars, showcasing the transformative impact of the ultimate shortcut for manufacturing on efficiency and success.

Lessons Learned and Best Practices

Examining the case studies provides valuable lessons and best practices for other manufacturers aspiring to revolutionize their processes. Insights from these success stories guide the implementation of automation, ensuring a smooth transition and optimal results.

Future Trends and Innovations in Pasta Manufacturing

Emerging Technologies

The future of pasta manufacturing holds exciting possibilities with emerging technologies playing a pivotal role. Advanced machinery, artificial intelligence, and data analytics are anticipated to further refine and optimize the manufacturing process. The ongoing pursuit of innovation ensures that the shortcut for manufacturing in the pasta industry continues to evolve.

Sustainability and the Shortcut for Manufacturing

The intersection of sustainability and the manufacturing shortcut is a crucial consideration for the future. As environmental consciousness grows, pasta manufacturers are expected to integrate eco-friendly practices into their automated processes. The sustainability aspect adds another layer to the efficiency-driven shortcut, aligning pasta production with global environmental goals.

Conclusion

Recap of the Ultimate Shortcut for Manufacturing

In conclusion, the ultimate shortcut for manufacturing in pasta production lies in the comprehensive adoption of fully automated processes. This article has explored how embracing automation enhances efficiency, ensures consistent product quality, and sets the stage for success in an ever-evolving industry.

Looking Ahead: A Revolutionized Future

Looking ahead, the pasta manufacturing landscape is poised for a revolutionized future. The ongoing integration of emerging technologies, coupled with a commitment to sustainability, promises a dynamic and competitive industry. Manufacturers who continue to embrace the ultimate shortcut for manufacturing are well-positioned to lead and thrive in this revolutionized future.

FAQs: Frequently Asked Questions about Shortcut for Manufacturing

Curious about the shortcut for manufacturing in pasta production? Here are answers to common questions.

1. What does "shortcut for manufacturing" mean in the context of pasta production?

- The term refers to the adoption of fully automated processes to streamline and optimize every stage of pasta manufacturing, enhancing efficiency and success.

2. How do companies like Barilla and De Cecco implement the shortcut for manufacturing?

- Leading companies implement fully automated systems, integrating advanced machinery to achieve precision, consistency, and increased production efficiency.

3. Is sustainability a part of the manufacturing shortcut in pasta production?

- Yes, sustainability is an integral aspect of the shortcut, with manufacturers expected to incorporate eco-friendly practices into automated processes.

4. What benefits can manufacturers expect from the ultimate shortcut for manufacturing?

- Manufacturers can enjoy increased production speed, cost savings, and enhanced product quality, leading to greater competitiveness in the market.

5. What does the future hold for the shortcut for manufacturing in pasta production?

- The future involves continuous innovation with emerging technologies and a heightened focus on sustainability, ensuring a revolutionized and dynamic industry.