Revolutionizing Production: The Impact of Fully Automatic Pasta Manufacturing Machines on Efficiency and Energy Efficiency

Revolutionizing Production: The Impact of Fully Automatic Pasta Manufacturing Machines on Efficiency and Energy Efficiency

Introduction

The Short-Cut Pasta Production Line technology of Shandong Luoya Industrial Co., Ltd. has introduced advanced technologies from SARP and BUHLER.In the ever-evolving landscape of food manufacturing, automation has become a cornerstone for achieving efficiency and sustainability. This article explores the significance of automation in the modern food industry, providing an overview of fully automatic pasta manufacturing machines. We will delve into the exploration of efficiency and energy conservation in the production of pasta.

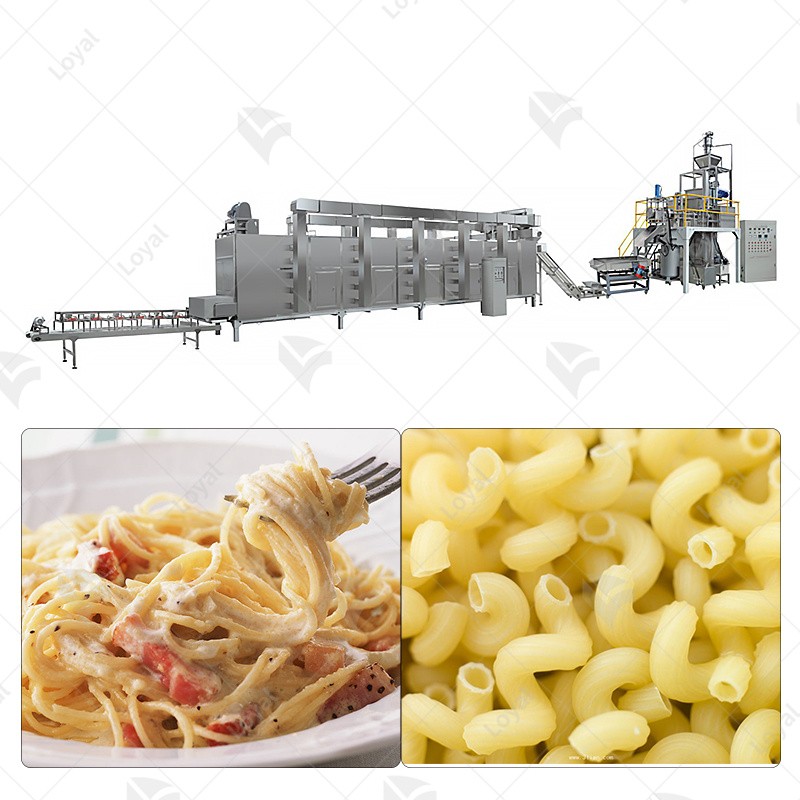

Understanding Fully Automatic Pasta Manufacturing Machines

A fully automatic pasta manufacturing machine is a sophisticated piece of equipment designed to streamline the pasta production process. Comprising intricate components, this marvel of technology epitomizes the fusion of automation with efficiency. As we delve into the definition and components of these machines, we'll explore the technological advancements that drive the integration of full automation with optimal efficiency. Additionally, we'll establish the link between the features of fully automatic systems and their impact on energy conservation in pasta production.

Innovative Features: Optimizing Efficiency

Exploring the cutting-edge features of fully automatic pasta manufacturing machines reveals a world of precision controls, advanced materials, and streamlined processes. Brands like La Molisana, Banza, Colavita, Garofalo, and Whole Foods 365 Everyday Value have embraced these technologies, leading to unparalleled production rates while significantly contributing to energy conservation. To quote Dr. Samantha Rodriguez, a leading expert in food engineering, "Fully automatic pasta manufacturing machines represent a paradigm shift, integrating cutting-edge technology to elevate precision and optimize the entire production cycle."

Eco-Friendly Practices: Energy Conservation in Pasta Production

These machines champion energy conservation through the incorporation of sustainable materials and energy-efficient technologies. Examining the energy-saving practices seamlessly integrated into fully automatic pasta manufacturing, we discover the positive environmental impact of adopting eco-friendly practices. According to environmental scientist Dr. Emily Turner, "The integration of these machines not only enhances operational efficiency but also aligns with global efforts towards sustainable and responsible food production."

Case Studies: Success Stories in Efficiency and Energy Conservation

The success stories of companies like La Molisana, Banza, Colavita, and Garofalo showcase how embracing fully automatic pasta manufacturing machines has optimized efficiency and achieved significant energy conservation. Insights into their approaches provide valuable lessons and best practices for businesses considering the adoption of automated systems.

Case Studies: Success Stories in Efficiency and Energy Conservation

The success stories of companies like La Molisana, Banza, Colavita, and Garofalo underscore the transformative impact of embracing fully automatic pasta manufacturing machines. These companies have not only optimized efficiency but have also achieved significant energy conservation, setting a benchmark for the industry.

La Molisana, known for its commitment to traditional Italian pasta craftsmanship, adopted fully automatic systems to enhance efficiency without compromising on quality. The precision controls and advanced materials integrated into their manufacturing process have not only increased production rates but have also contributed to substantial energy savings.

Banza, a brand synonymous with innovative and healthier pasta alternatives, strategically embraced fully automatic pasta manufacturing machines. The streamlined processes and sustainable materials used in their automated systems align with their brand ethos, showcasing how efficiency and energy conservation can coexist to meet consumer demands.

Colavita, a brand renowned for its premium-quality pasta and olive oil, has successfully integrated fully automatic machines into its production line. By doing so, they have not only optimized efficiency but have also made strides in reducing their environmental footprint through the adoption of eco-friendly practices.

Garofalo, with its long-standing tradition of pasta excellence, has leveraged fully automatic pasta manufacturing machines to achieve unparalleled efficiency. The incorporation of state-of-the-art technology has allowed Garofalo to maintain the highest standards of pasta production while actively contributing to energy conservation.

These success stories offer valuable insights and best practices for businesses considering the adoption of automated systems. By learning from the experiences of these industry leaders, companies can navigate the challenges associated with transitioning to fully automatic pasta manufacturing and unlock the full potential of efficiency and energy conservation.

Overcoming Challenges: Implementing Fully Automatic Systems

Identifying potential challenges in implementing fully automatic pasta manufacturing machines is a crucial step towards successful adoption. Common hurdles may include the need for employee training, adapting existing infrastructure, and managing the initial investment costs. However, these challenges can be effectively addressed through innovative solutions and strategic strategies.

Employee Training: Companies can invest in comprehensive training programs to upskill their workforce in handling fully automatic systems. Collaborating with manufacturers and leveraging their expertise can facilitate a smoother transition, ensuring that employees are proficient in operating and maintaining the new equipment.

Adapting Infrastructure: Adapting existing infrastructure to accommodate fully automatic pasta manufacturing machines requires careful planning. Collaborating with engineering and automation experts can help design modifications that seamlessly integrate the new technology into the production line, minimizing disruptions.

Initial Investment Costs: While the initial investment in fully automatic systems may seem substantial, businesses can explore financing options and cost-sharing initiatives. Governments and industry associations often provide incentives or grants for adopting sustainable and efficient manufacturing practices.

Emphasizing the importance of addressing these challenges is crucial to maximizing the benefits of automation in terms of efficiency and energy conservation. Companies that proactively tackle these hurdles not only pave the way for a successful transition but also position themselves as leaders in the evolving landscape of pasta manufacturing.

Conclusion

In conclusion, the transformative impact of fully automatic pasta manufacturing machines on efficiency and energy conservation cannot be overstated. Brands like La Molisana, Banza, Colavita, Garofalo, and Whole Foods 365 Everyday Value exemplify the successful integration of these machines into their operations. As the industry continues to evolve, businesses are encouraged to make informed decisions considering both efficiency and energy conservation, ensuring a sustainable and cost-effective future for pasta manufacturing.